Work in progress

Net-Zero Steel Pathways

2024

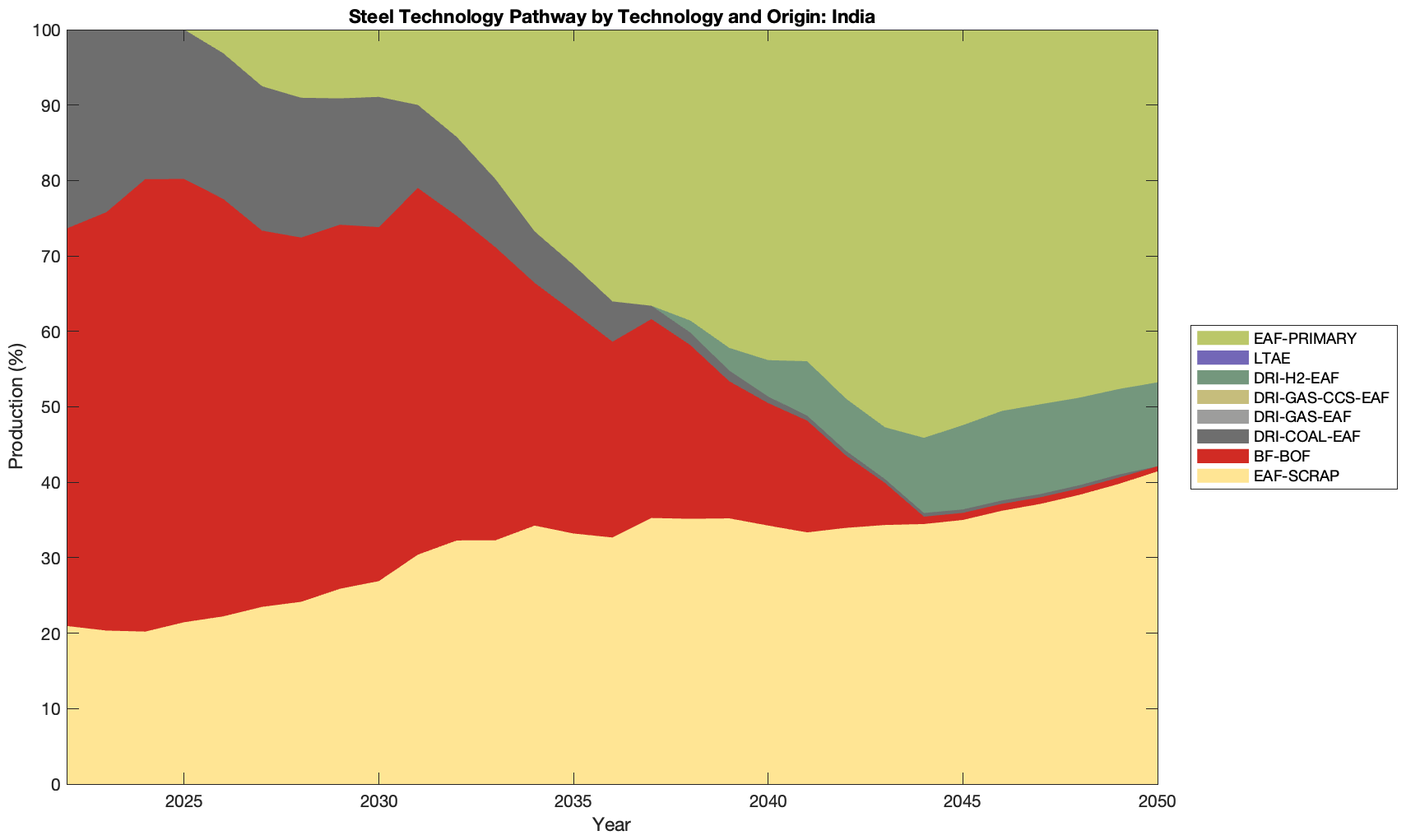

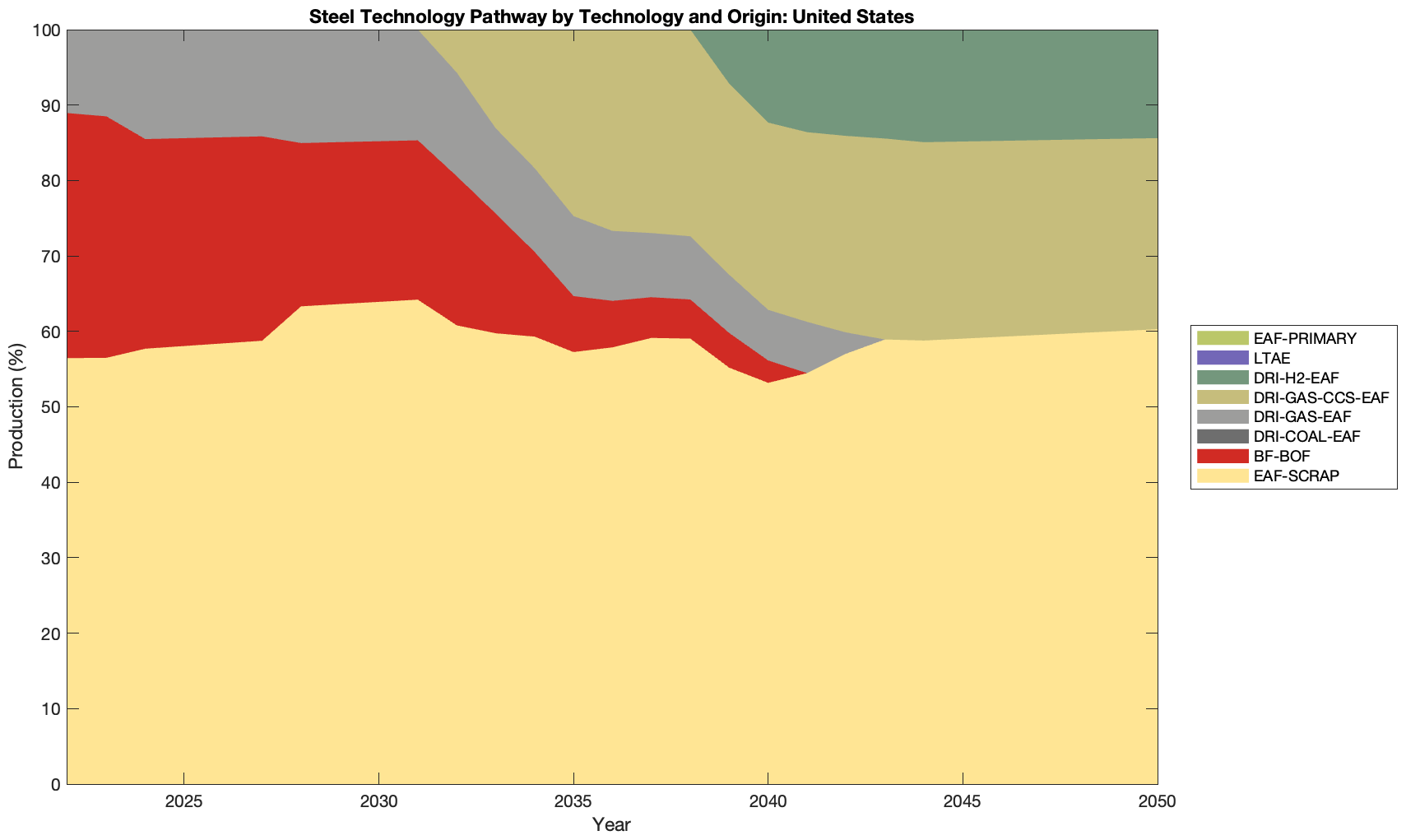

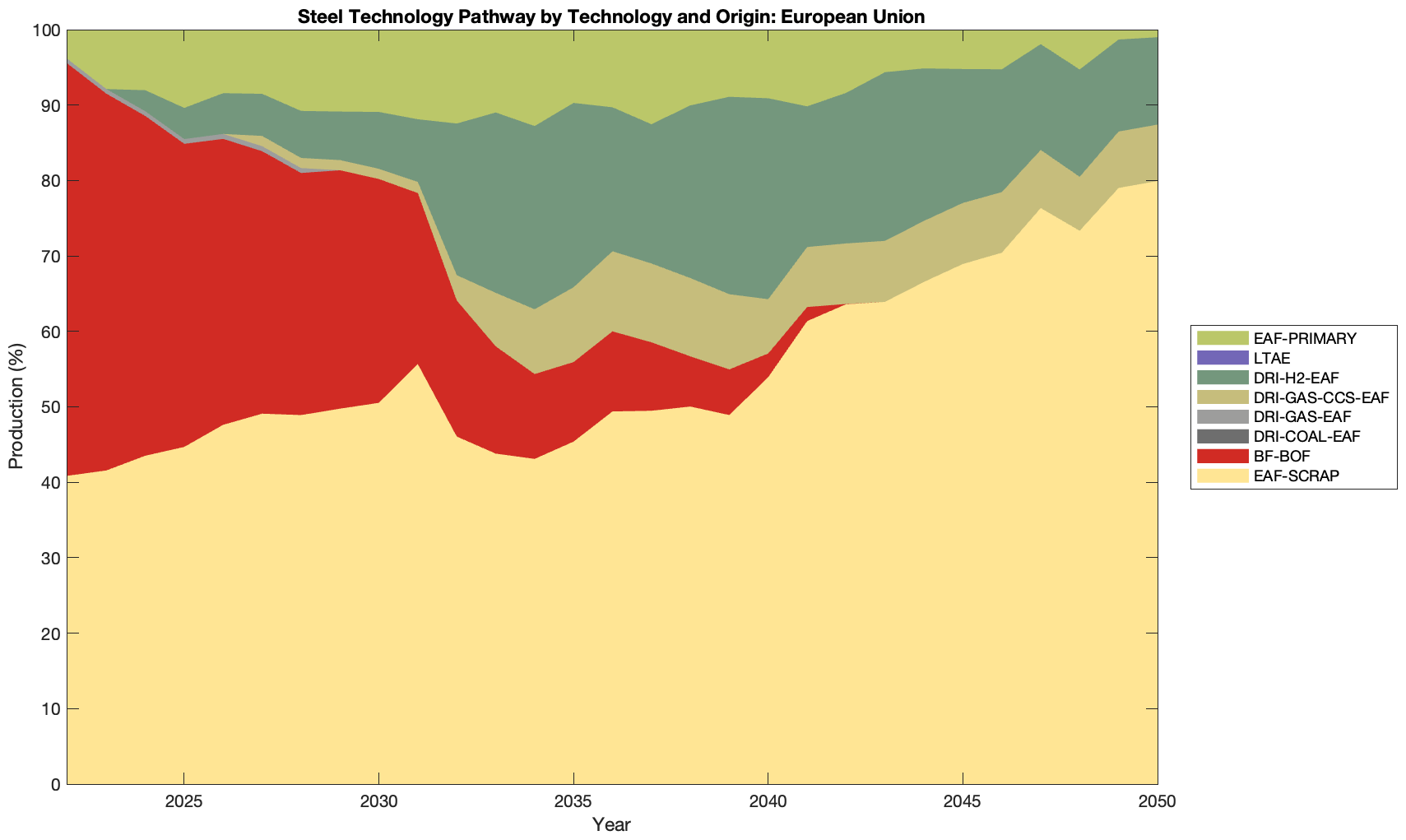

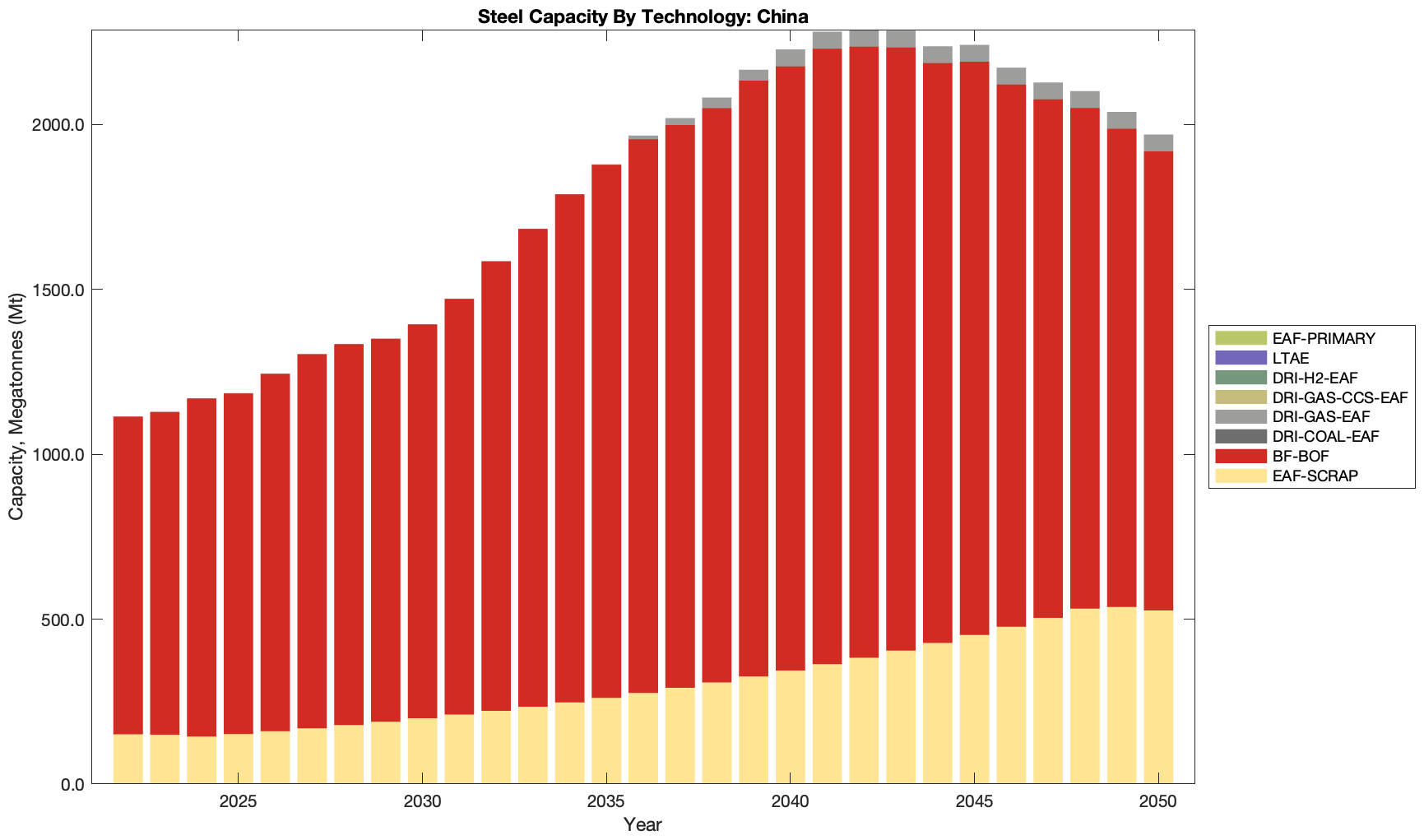

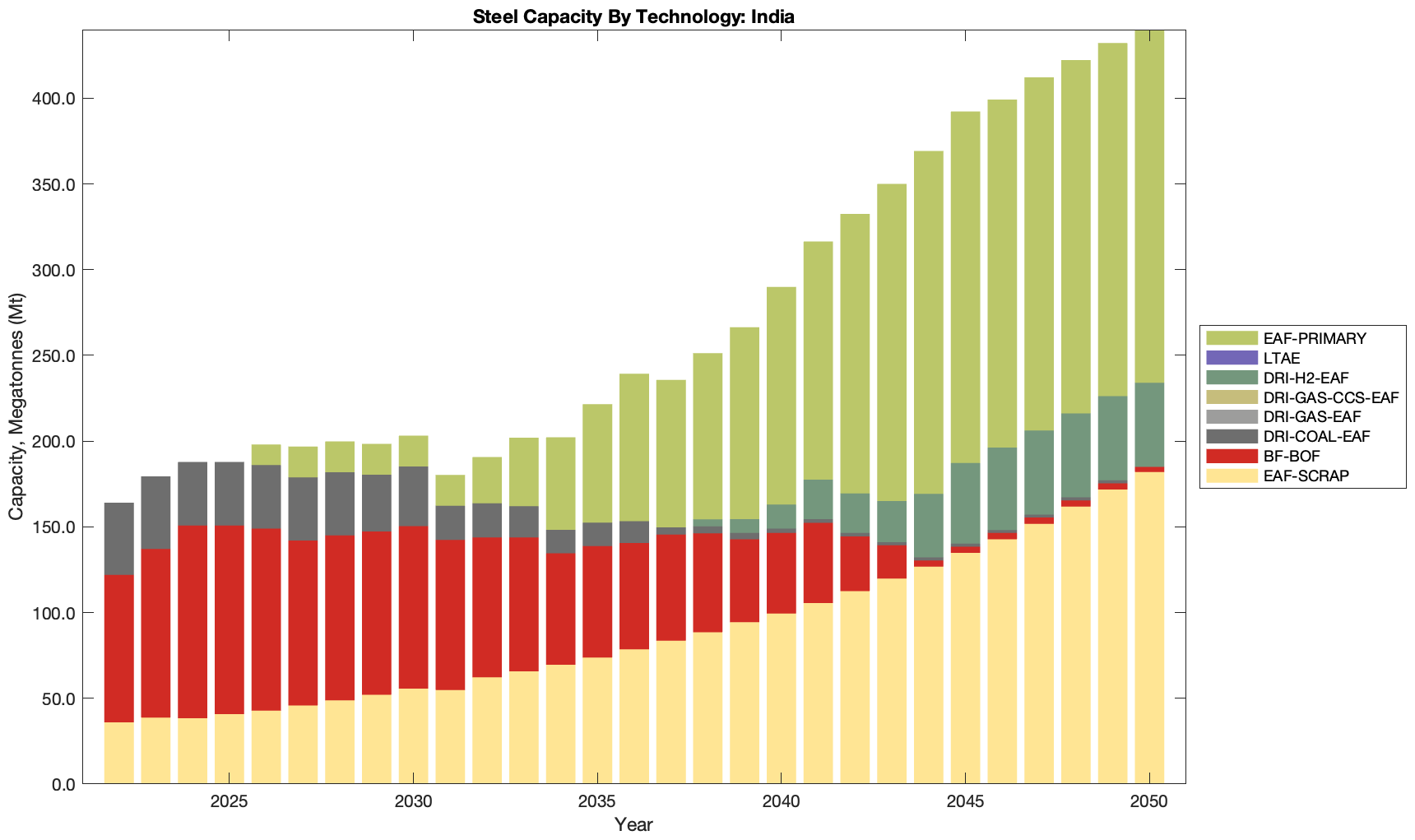

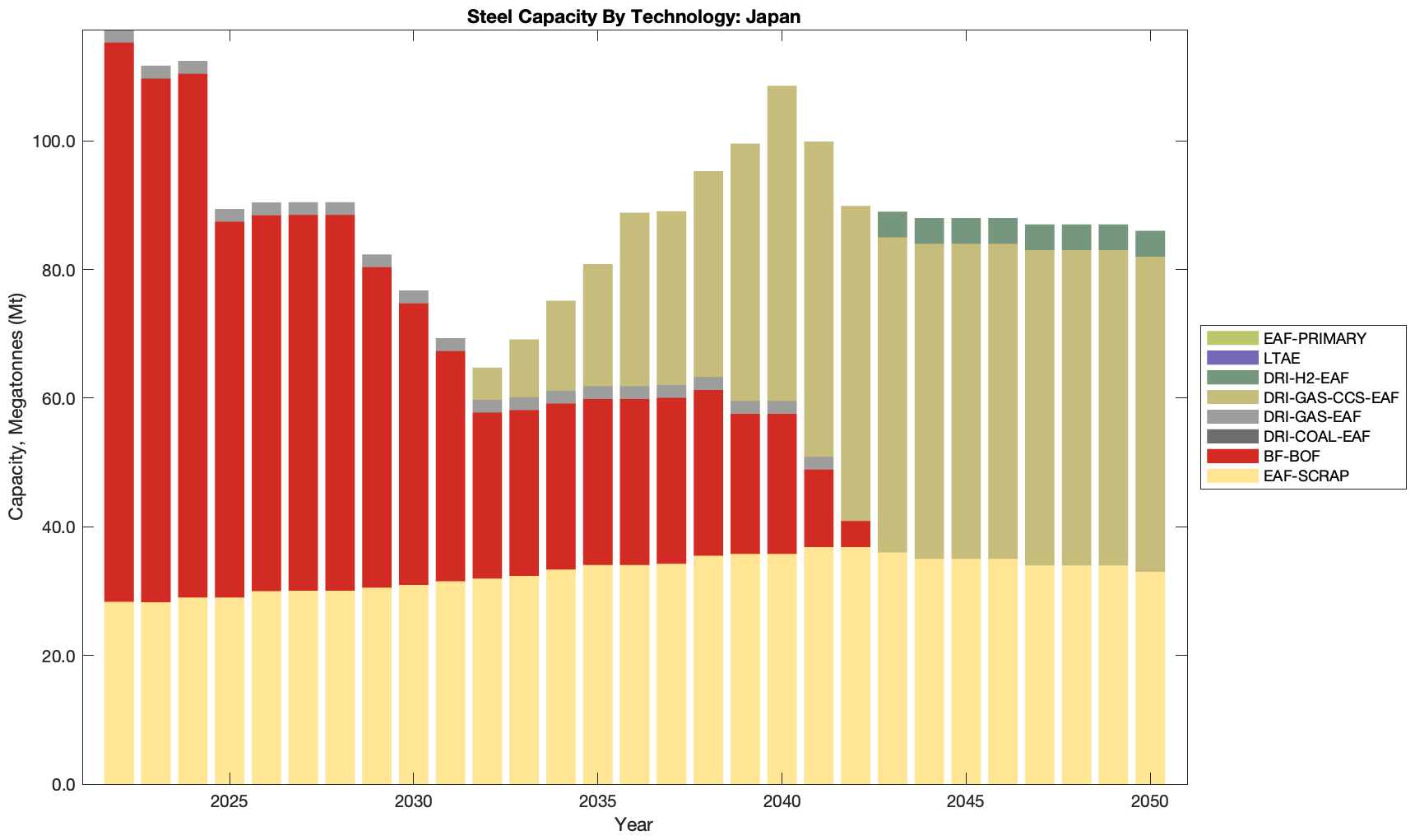

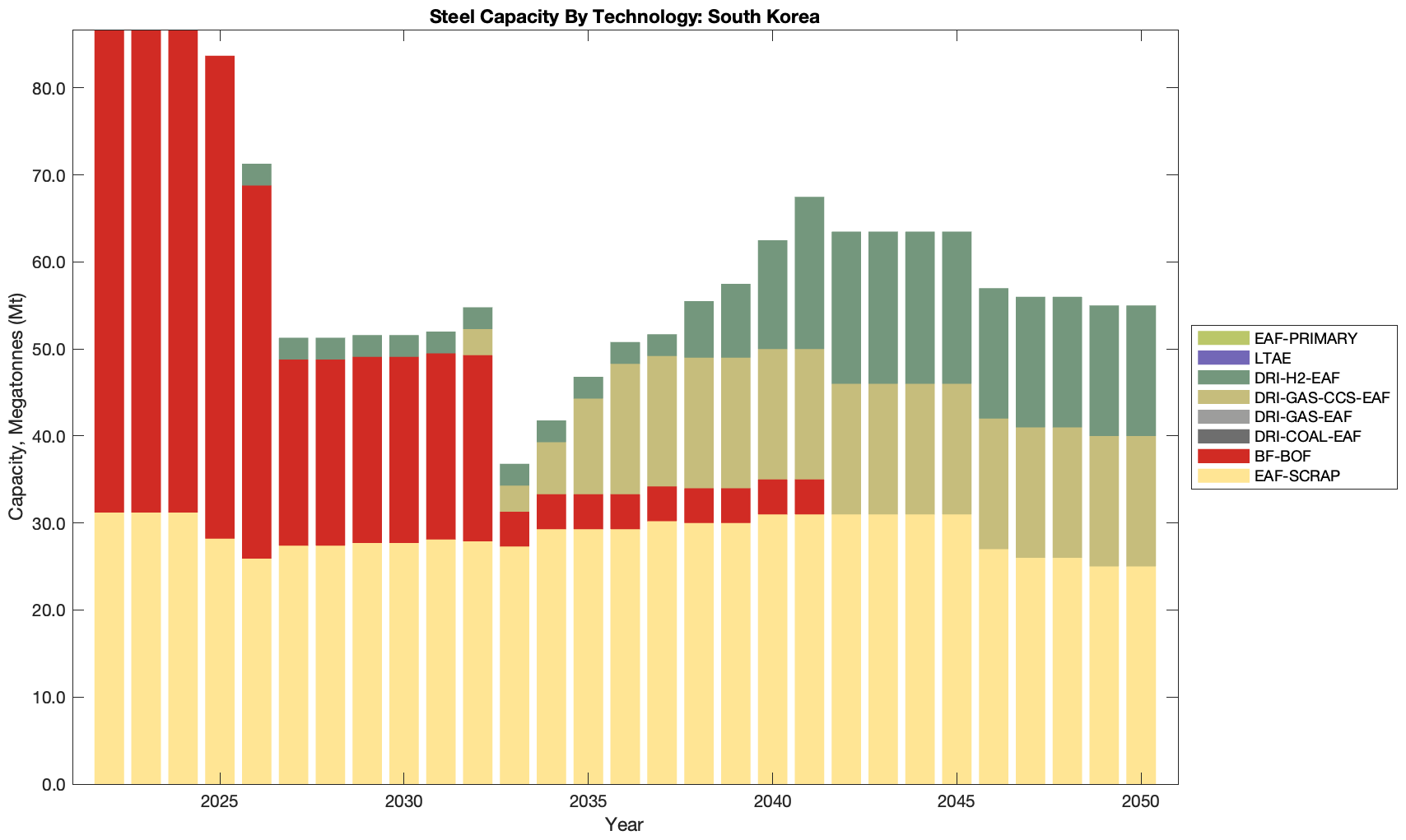

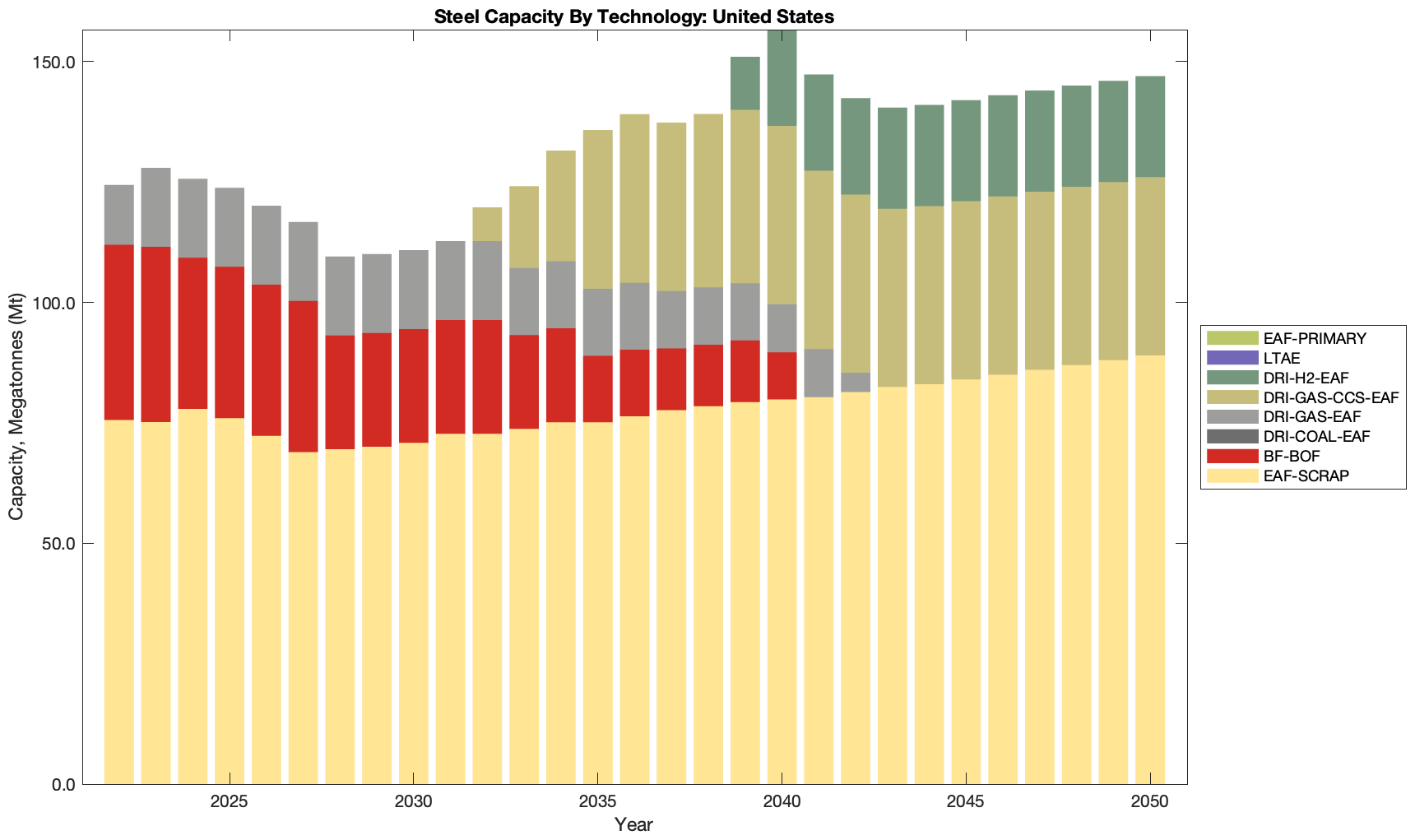

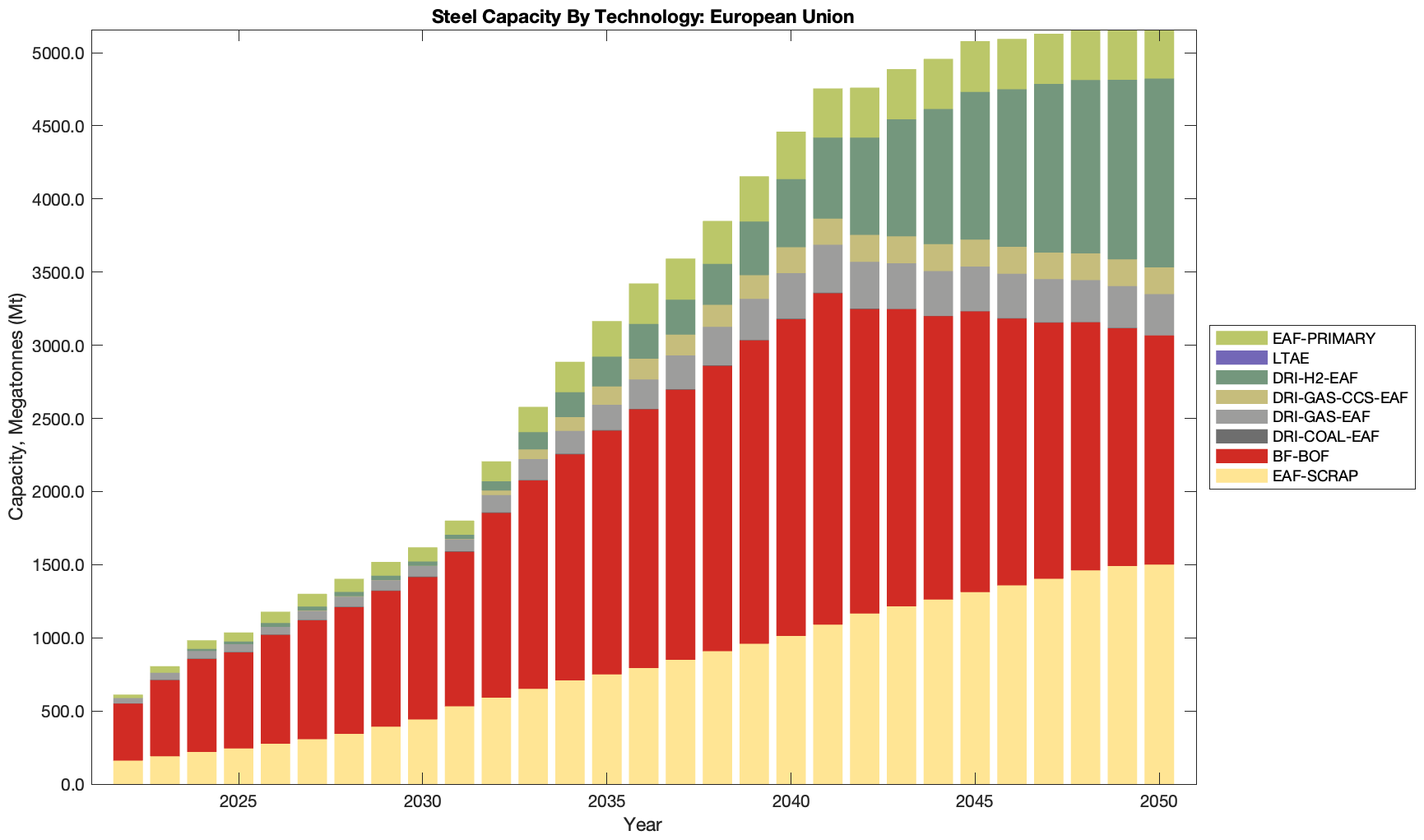

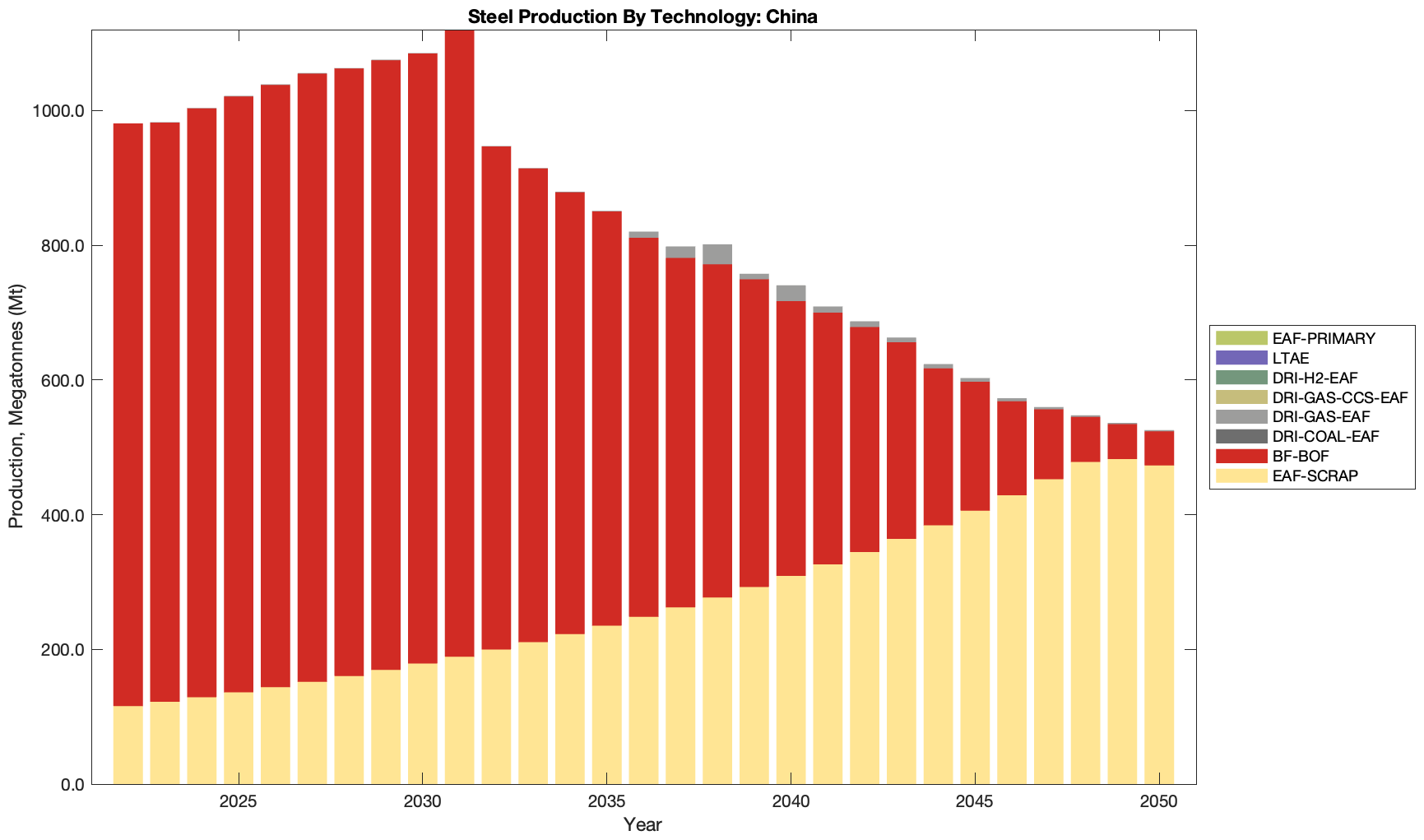

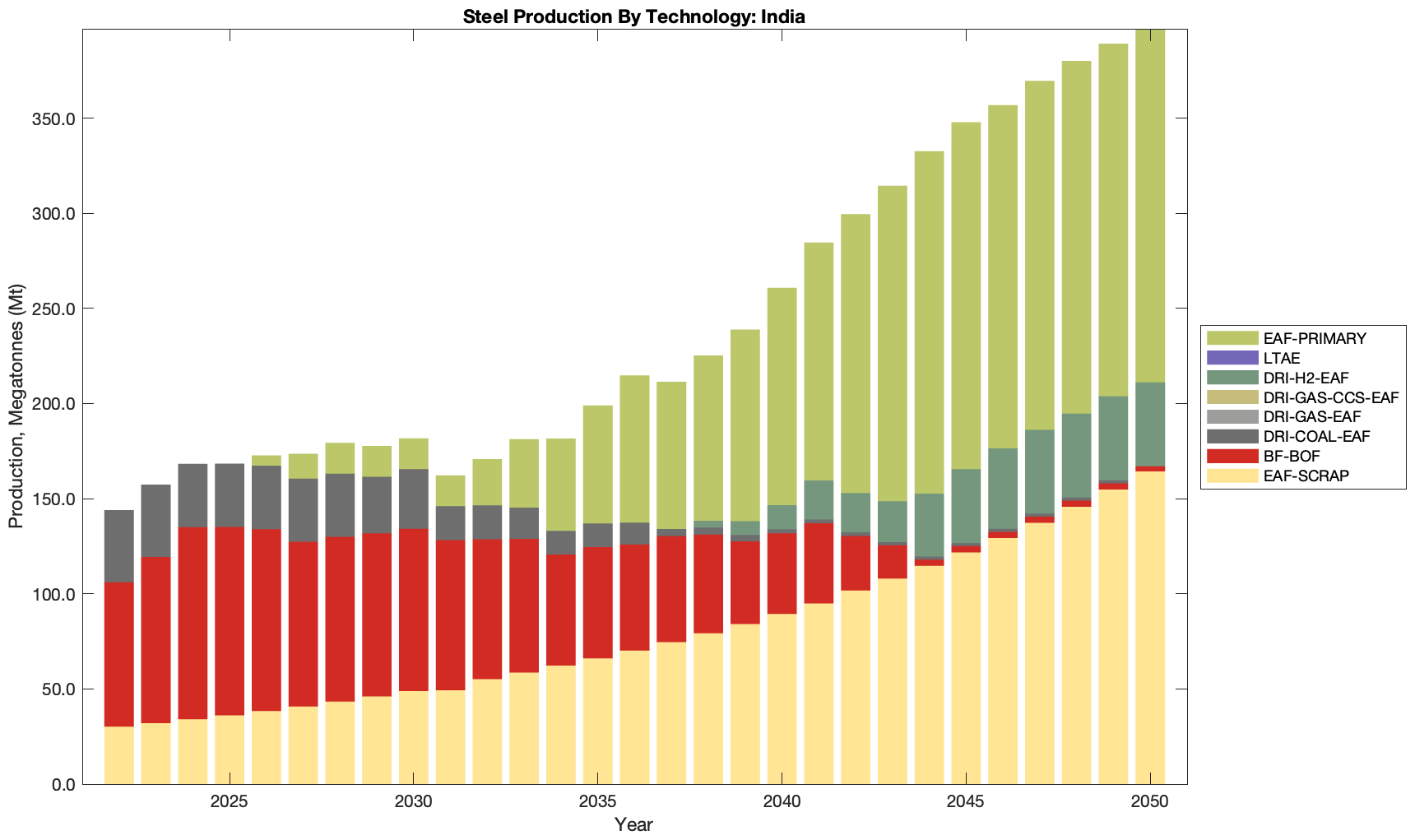

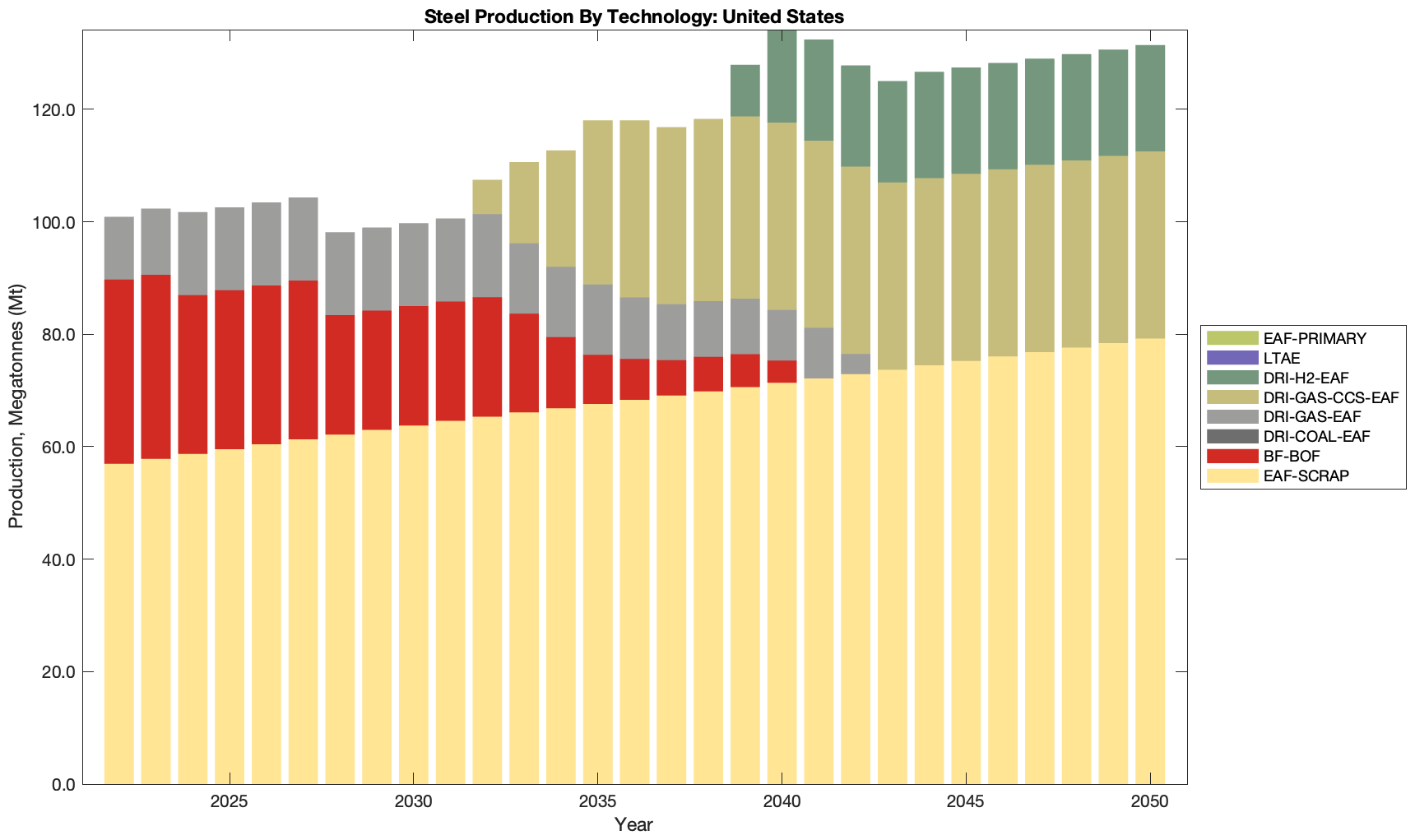

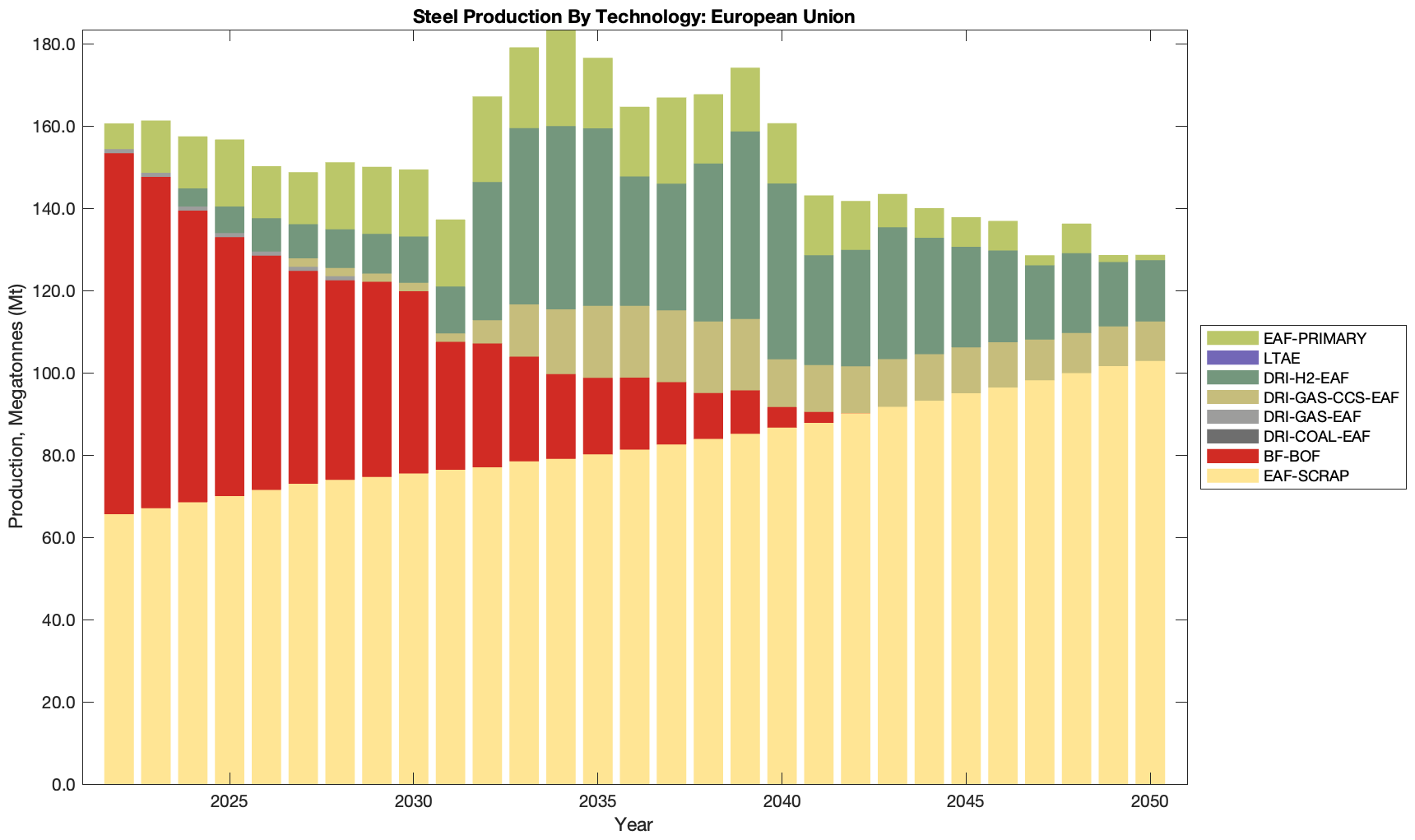

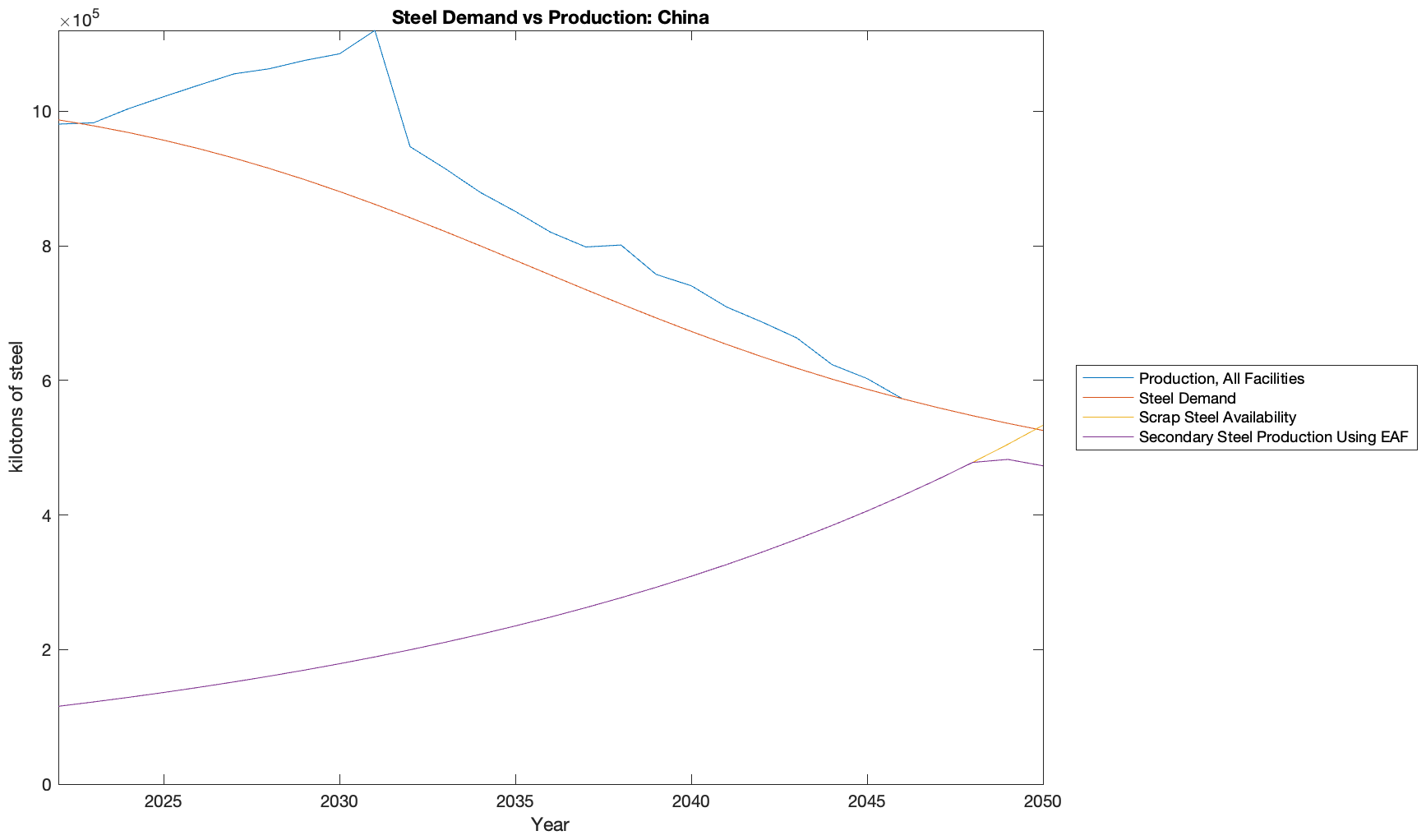

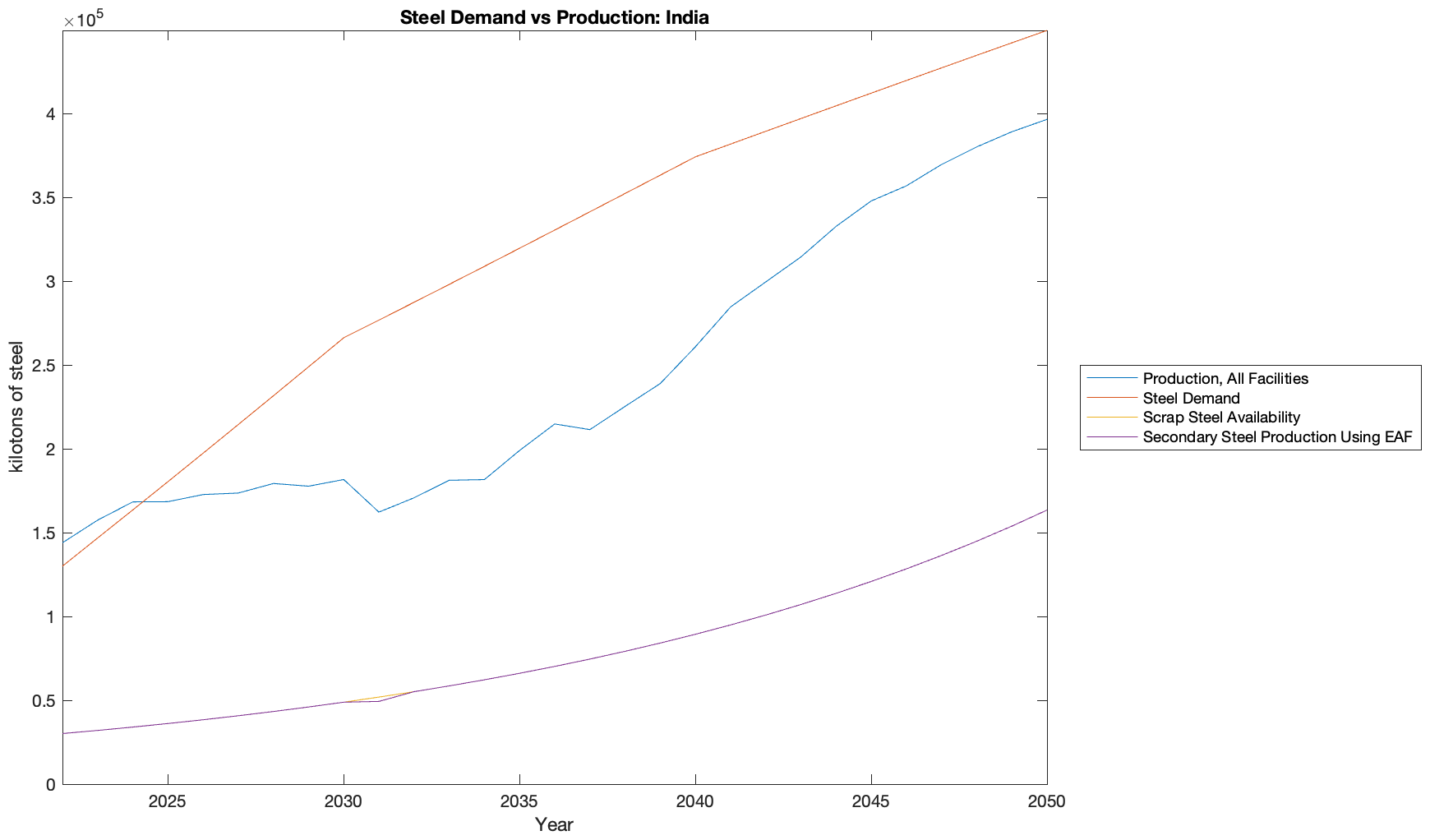

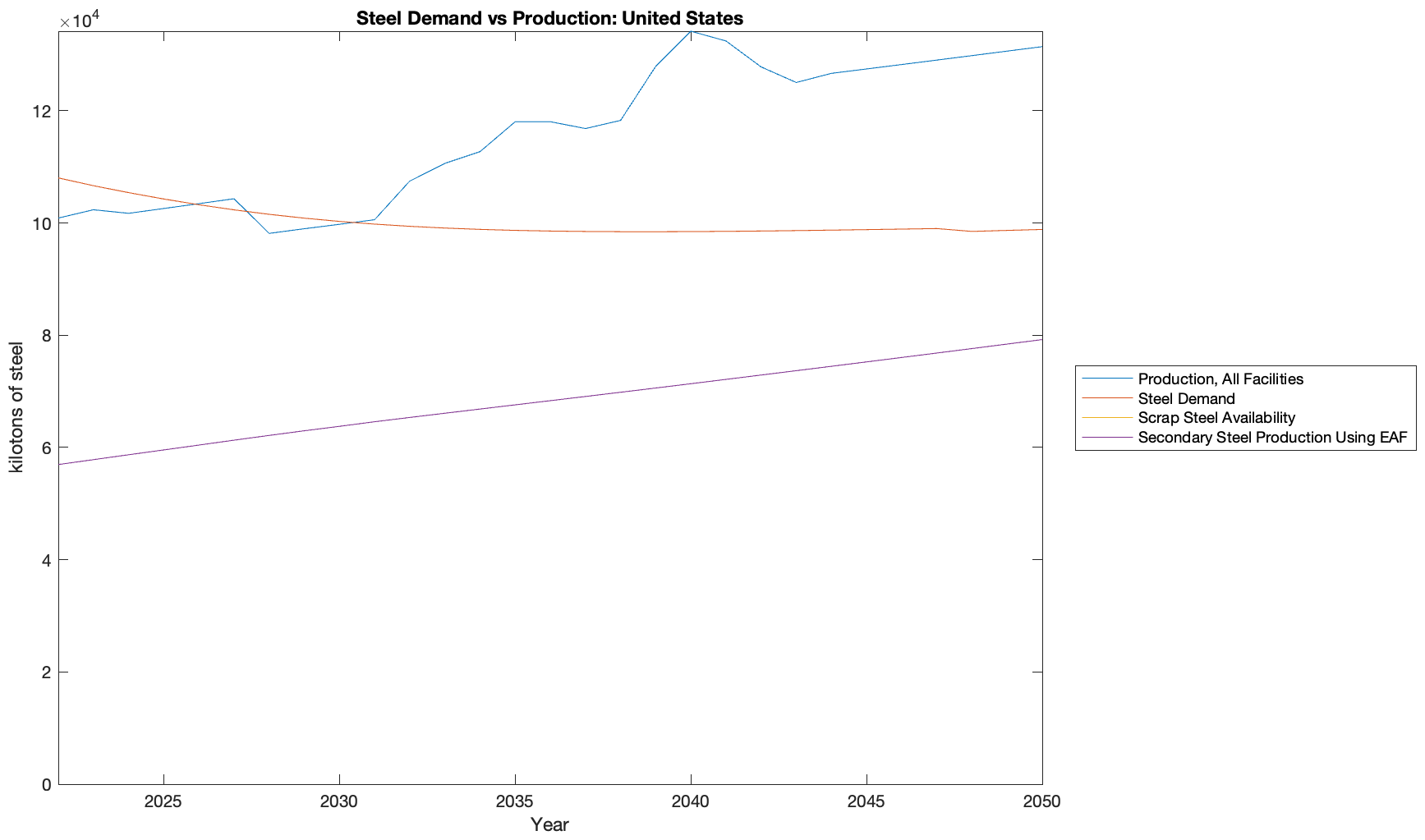

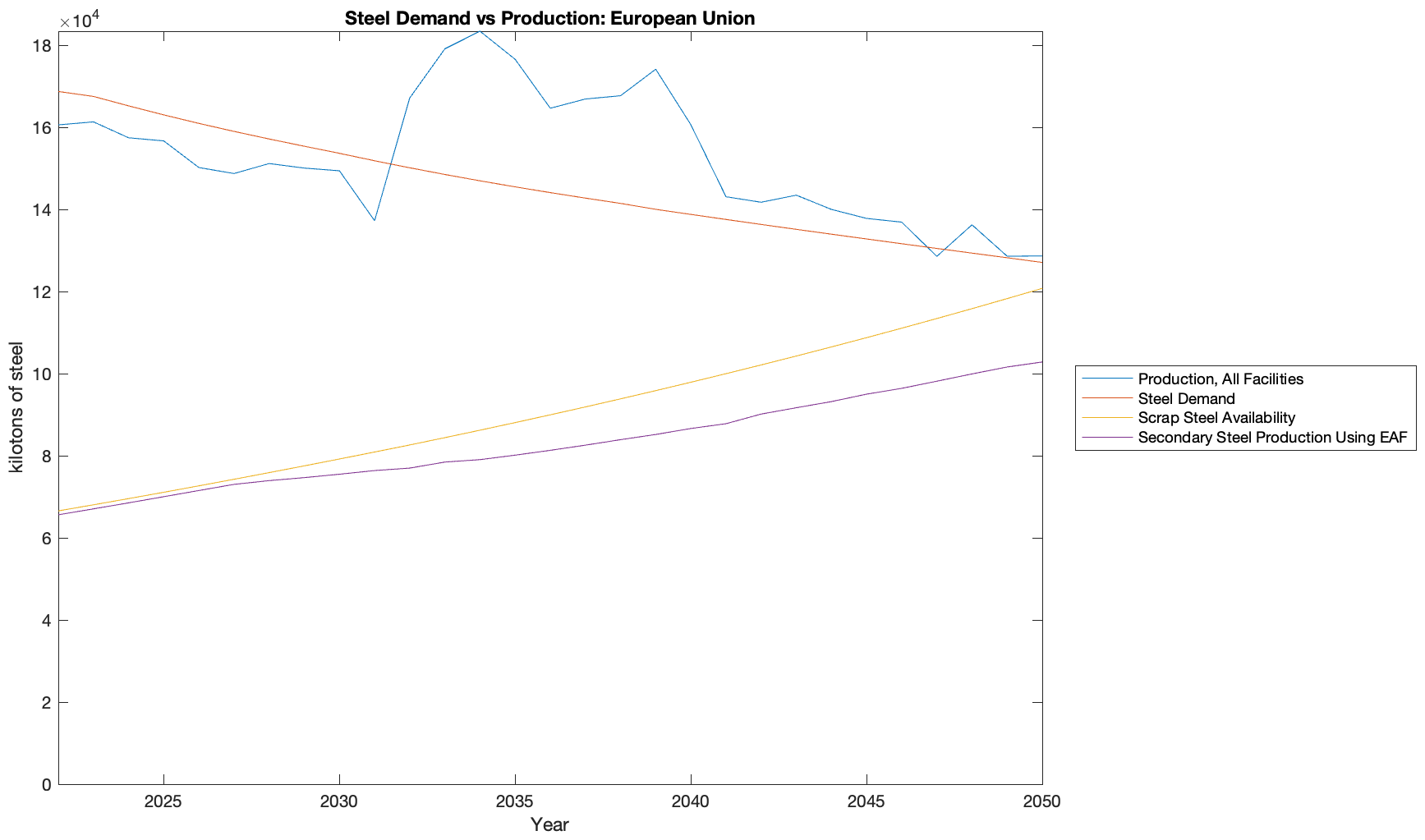

By 2050, under the Baseline scenario, global steel production becomes significantly more geographically diverse, shifting away from its 2021 concentration in Northeast Asia. Production grows notably in Southeast Asia, South Asia (especially India), the Middle East, Africa, and South America. In Europe, China, and the U.S., most domestic steel facilities transition to recycling using electric arc furnaces (EAFs).

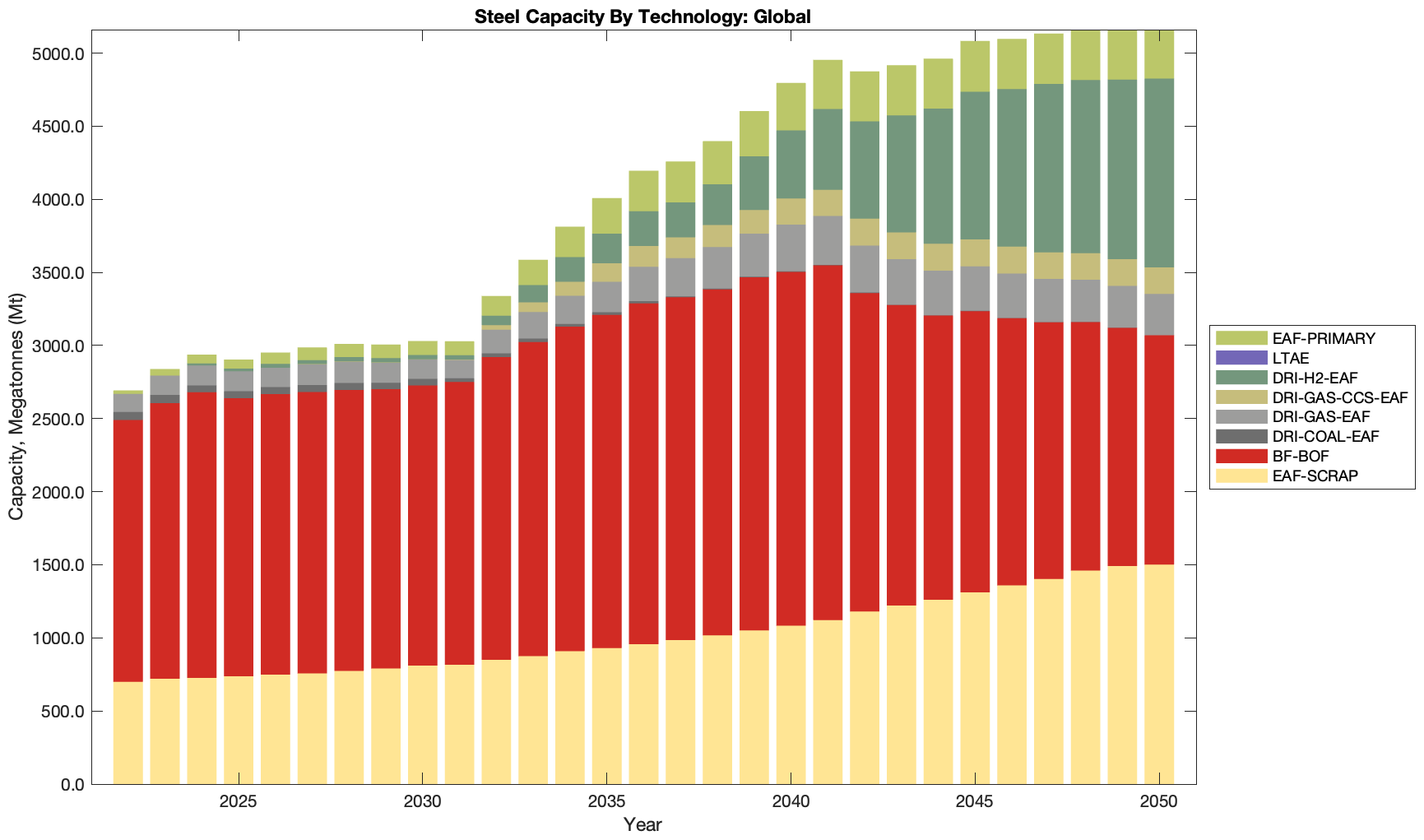

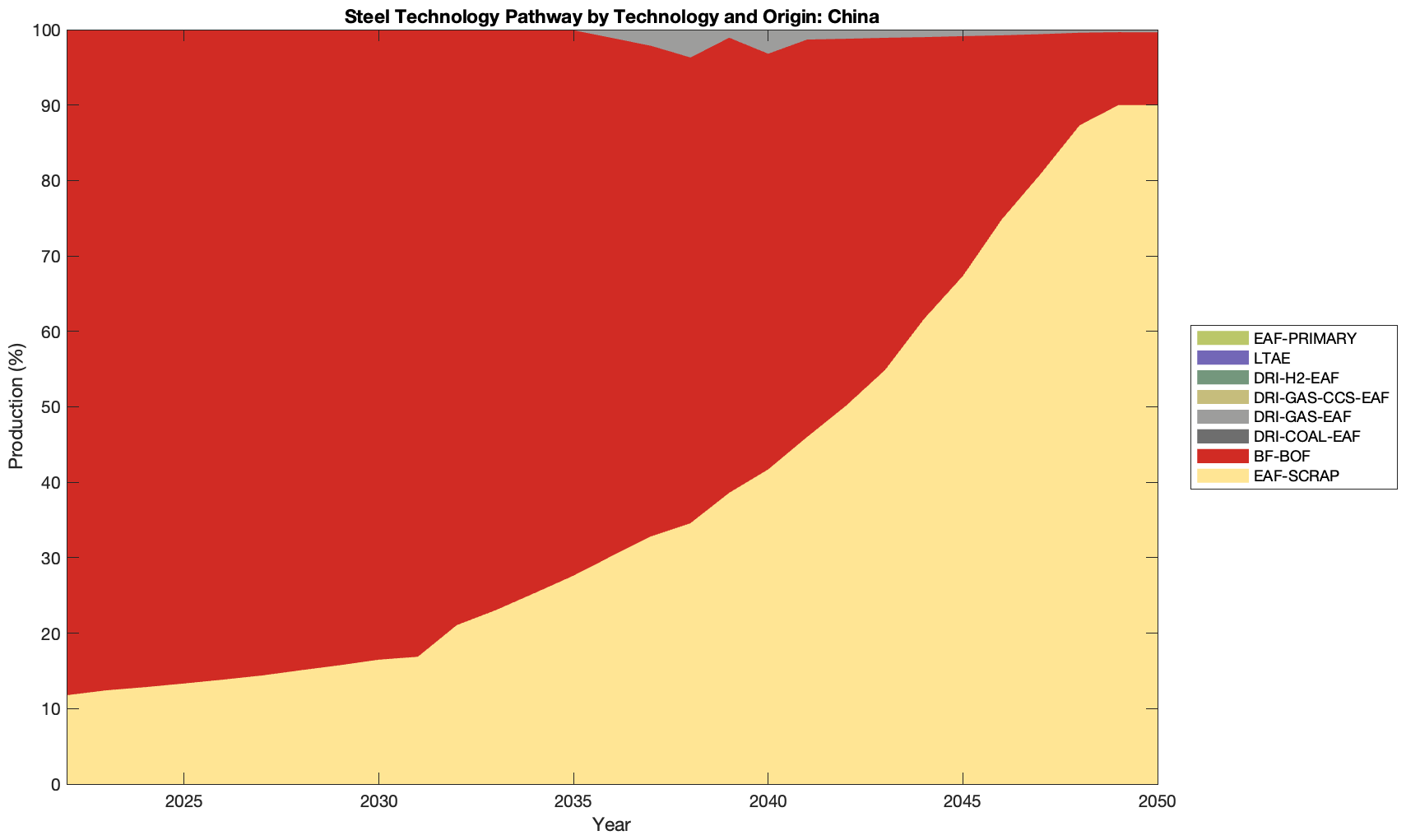

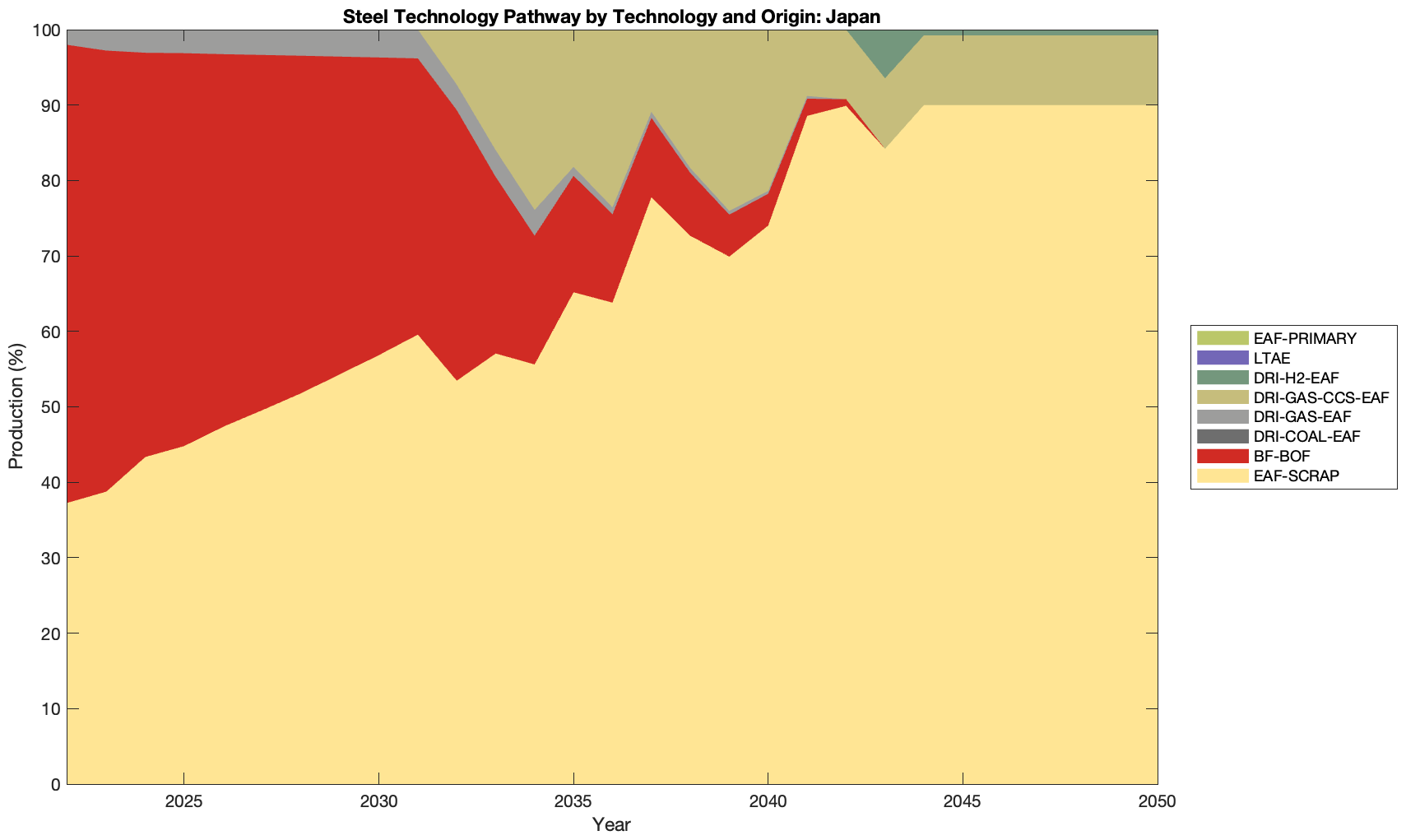

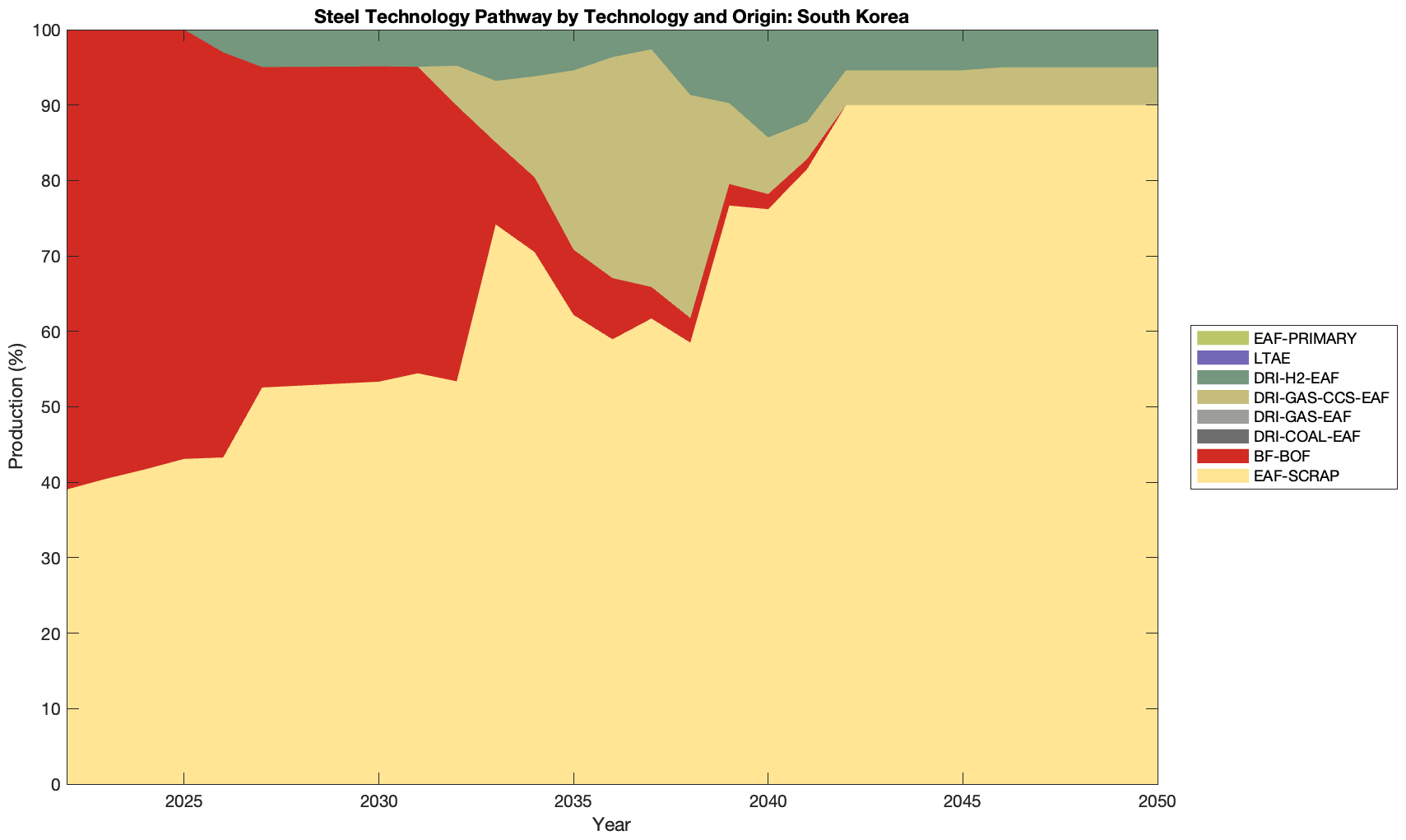

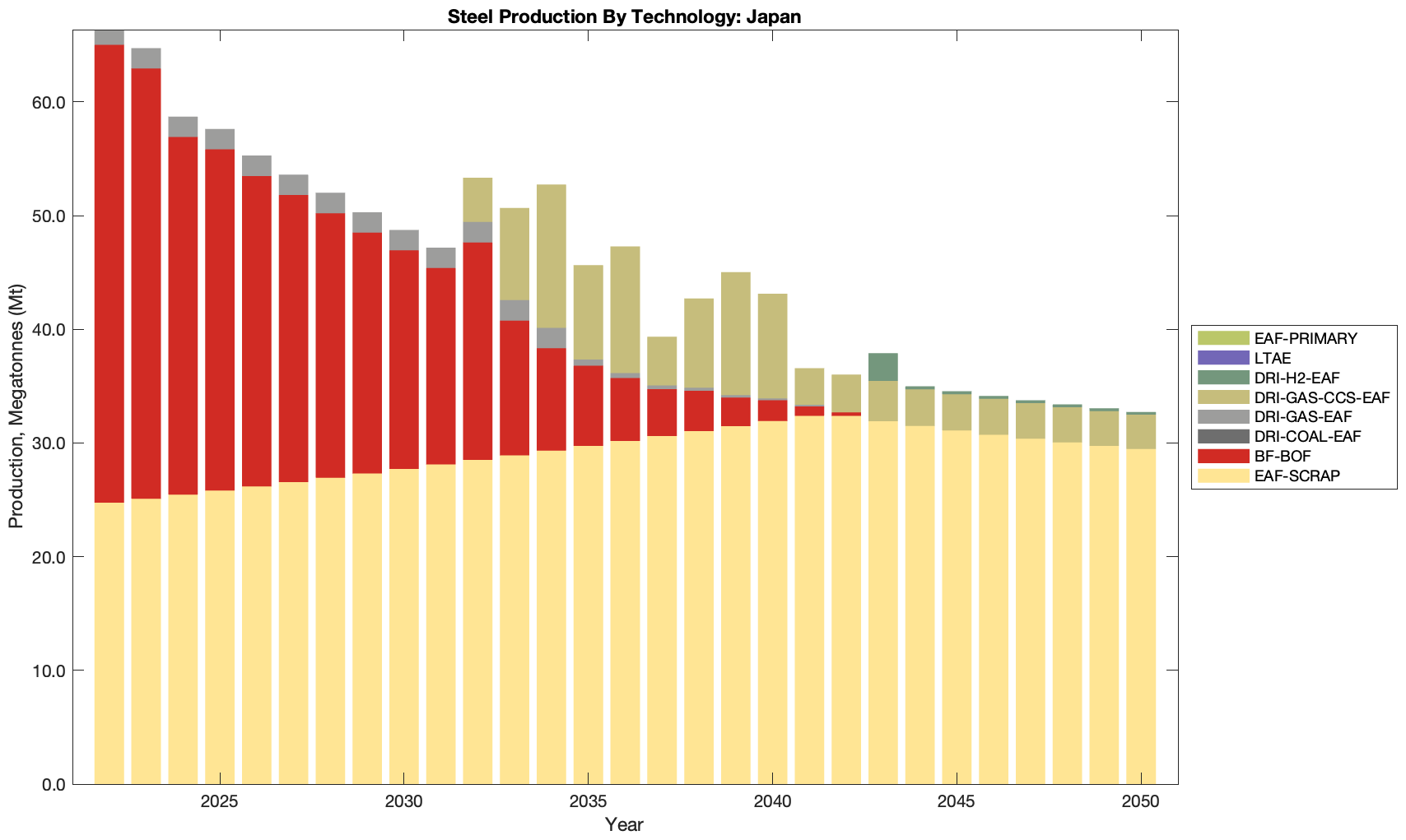

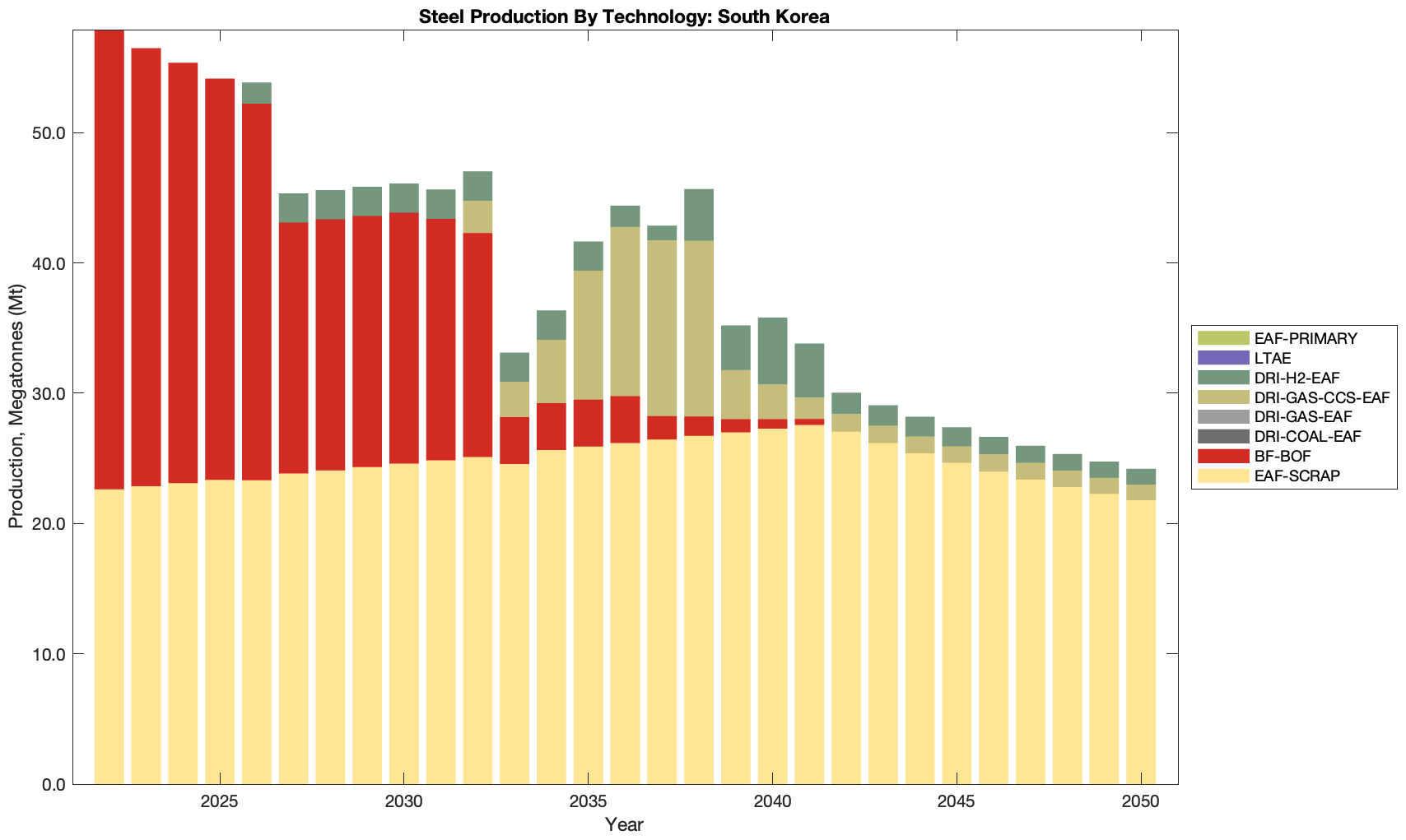

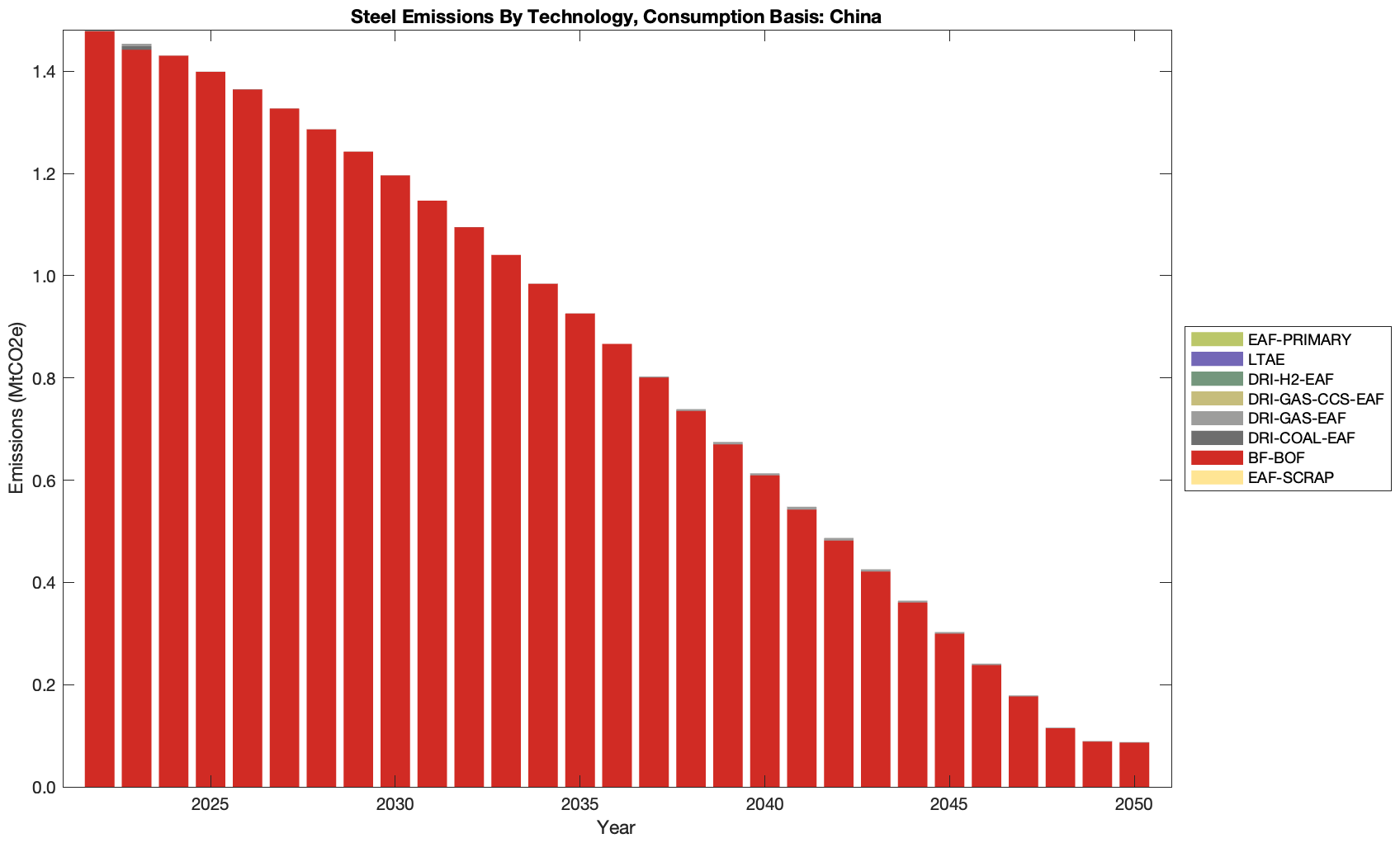

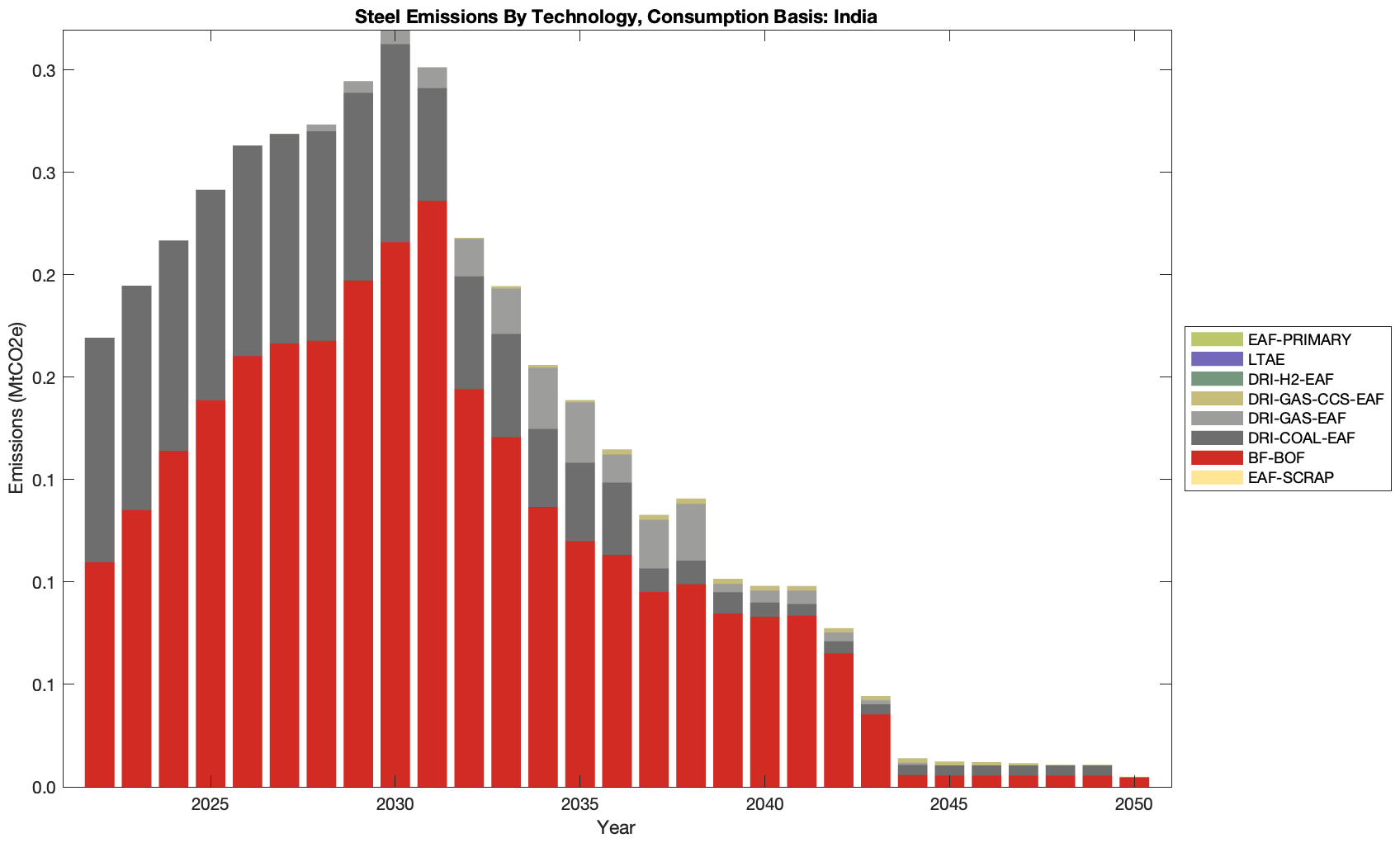

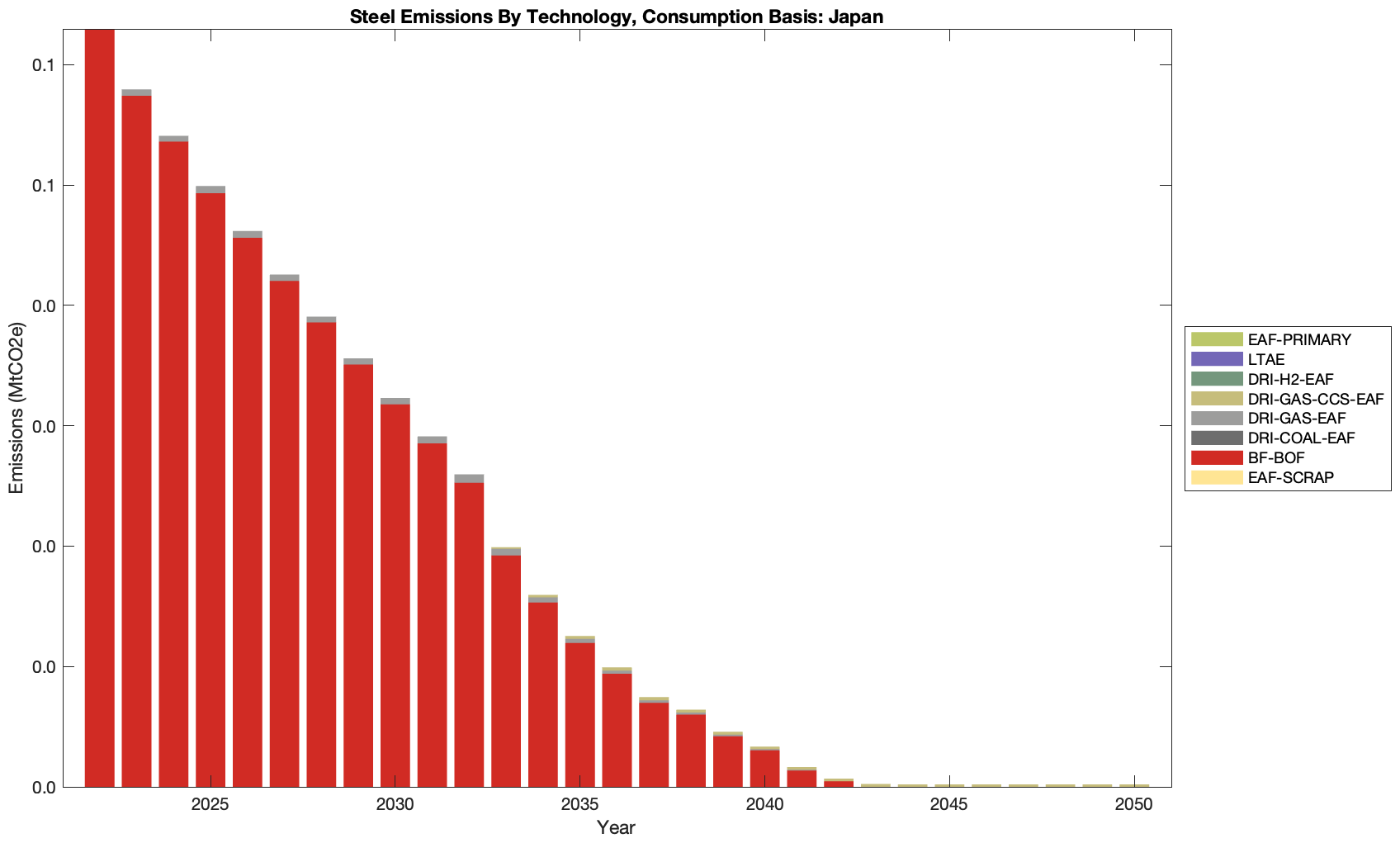

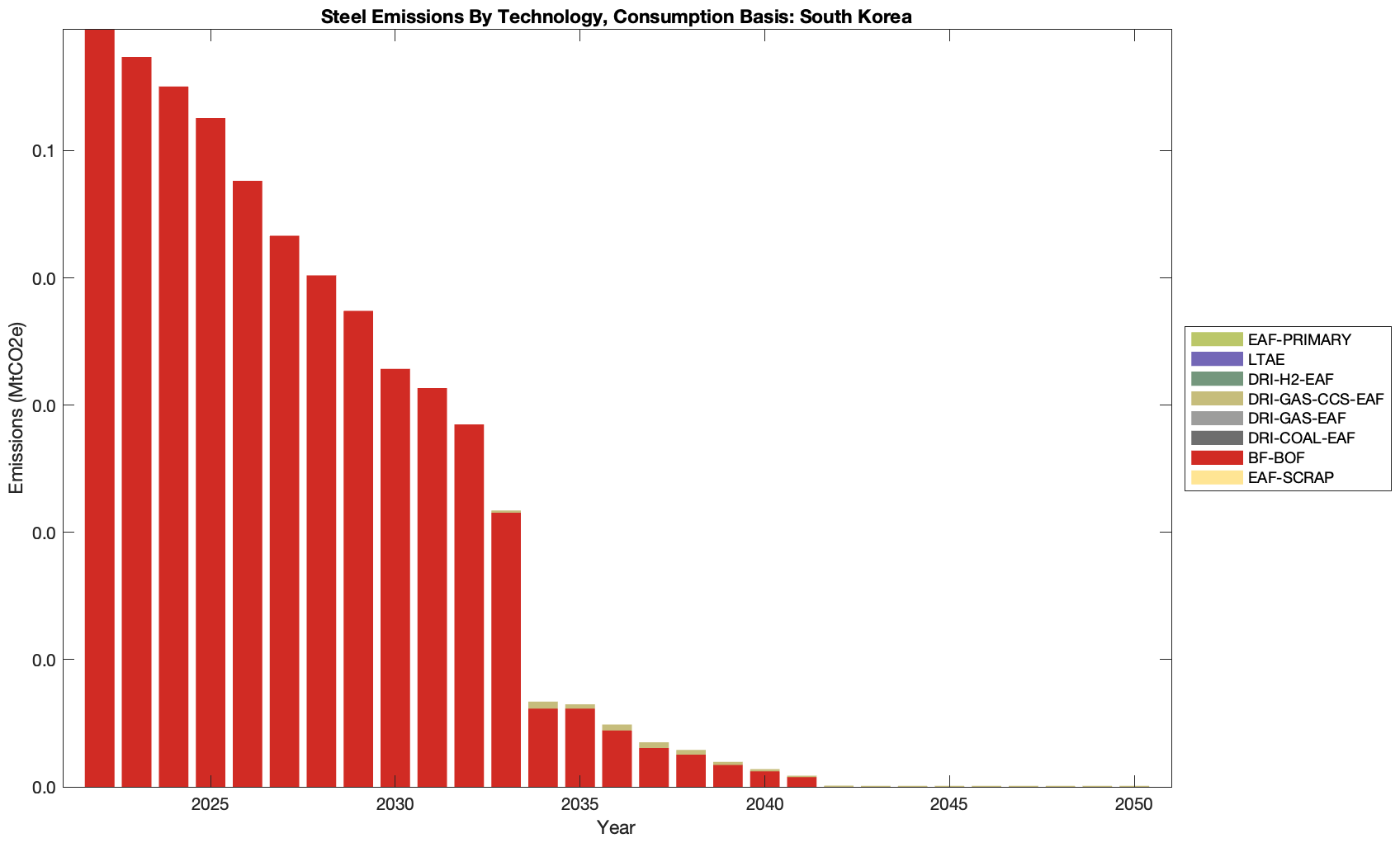

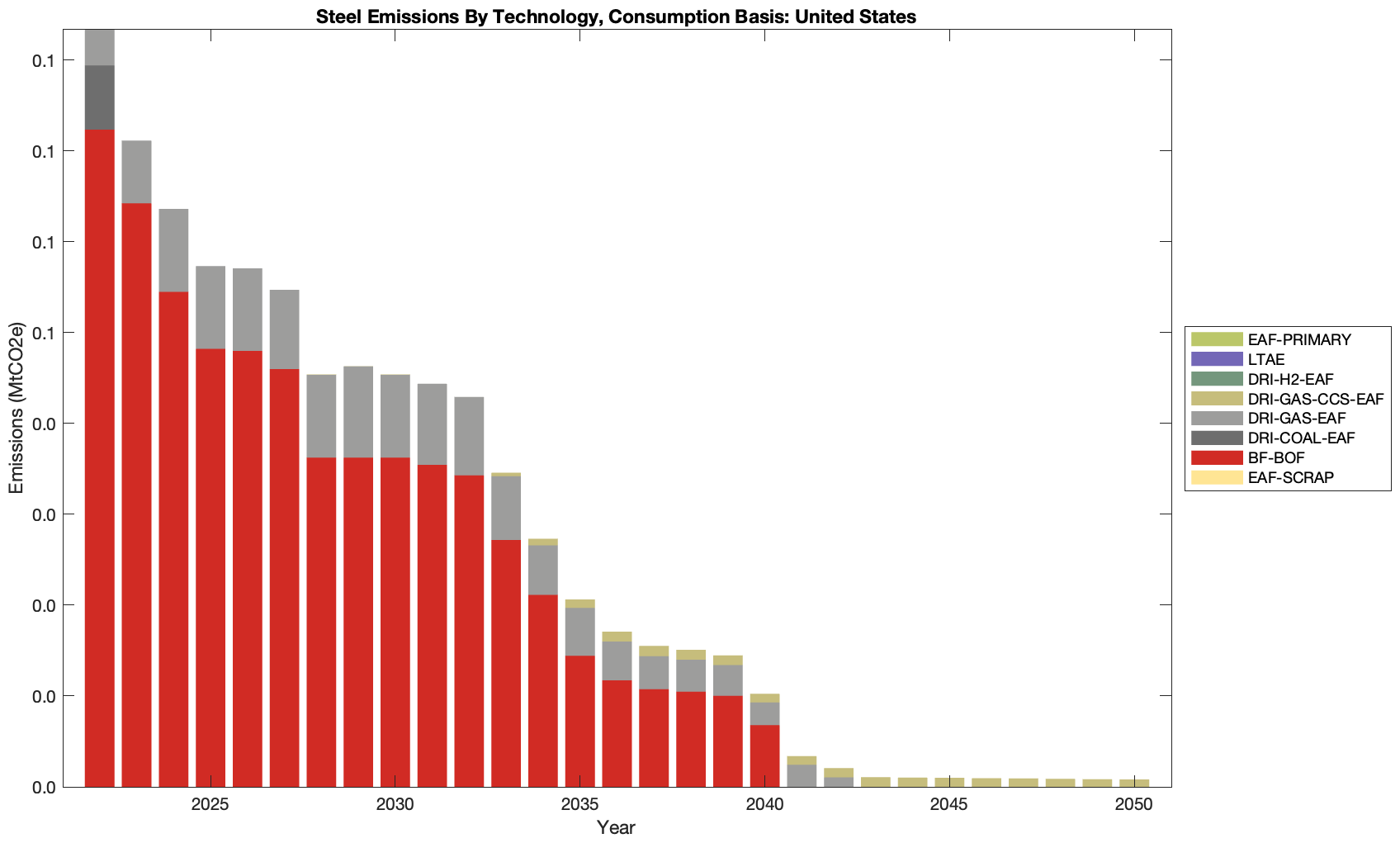

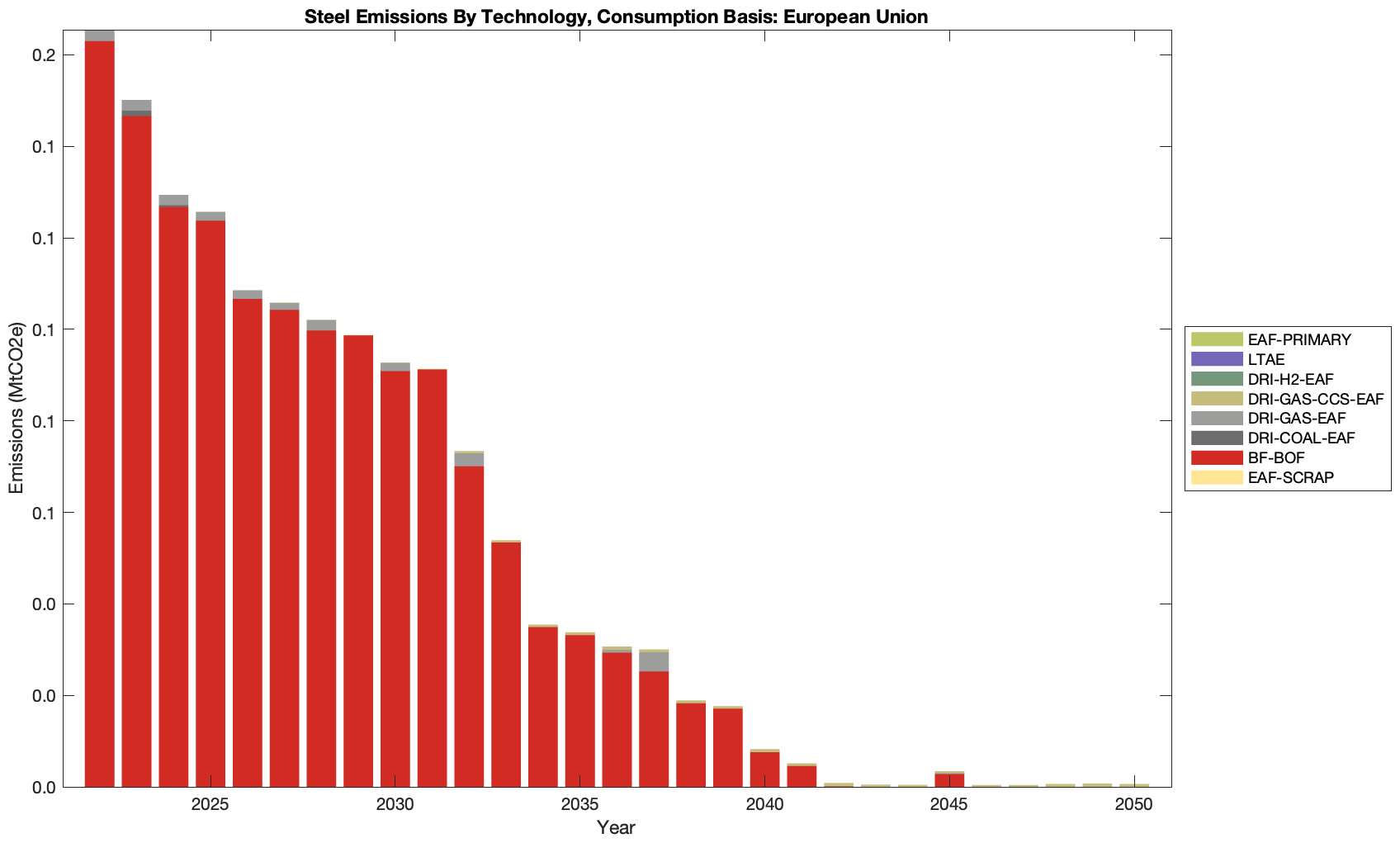

When comparing three climate policy scenarios—Narrow Club, Broad Club, and Broad Club Fossil Fuel Ban—four consistent trends emerge for 2050. First, primary steel production spreads more evenly across the globe, with growth across Southeast Asia, South Asia, Africa, and the Americas. Second, the dominance of coal-based Basic Oxygen Furnace steelmaking (BF-BOF) declines significantly. Third, steel recycling through EAF-SCRAP rises sharply. Lastly, there’s substantial growth in green steel production, including methods using imported green iron (EAF-PRIMARY) and hydrogen-based direct reduced iron (DRI-H2-EAF). These developments suggest a broad global shift toward cleaner, more sustainable steelmaking technologies across all modeled policy futures.

The Broad Club Fossil Fuel Ban scenario involves the same inclusive membership as the Broad Club, comprising the EU/EEA, USMCA, Japan, South Korea, Australia, New Zealand, the ASEAN Free Trade Area (AFTA), and significant iron producers including Brazil, South Africa, India, Guinea, Ukraine, and Venezuela. The defining feature of this scenario is the introduction of a ban on fossil fuel-based steel production among club members starting in 2025. Consistent with other club scenarios, a 30% tariff is applied to steel imports from outside the club, alongside a GHG intensity-based tariff, modeled after the EU CBAM, to harmonize carbon prices for imported steel. Members continue providing a subsidy of $100 USD (2020) per tonne for green iron production, reflecting both domestic policy initiatives and foreign investments. A uniform, substantial carbon price of $500 per tCO₂e is adopted by all club members beginning in 2025. Outside the club, countries maintain moderate decarbonization efforts with carbon pricing or equivalent measures set at $30 per tCO₂e in 2022, escalating to $100 per tCO₂e by 2050.

Geospatial of Steel Production in Broad Club Fossil Fuel Ban Scenario

| BF-BOF | Blast Furnace with Basic Oxygen Furnace | |

| DRI-COAL-EAF | Direct Reduction of Iron with Coal, followed by Electric Arc Furnace | |

| DRI-GAS-CCS-EAF | Direct Reduced Iron with Natural Gas, followed by Electric Arc Furnace, 90% of CO2 is Captured and Stored | |

| DRI-GAS-EAF | Direct Reduced Iron with Natural Gas, followed by Electric Arc Furnace | |

| DRI-H2-EAF | Direct Reduced Iron with Green Hydrogen, followed by Electric Arc Furnace | |

| LTAE | Ladle-Treatment and Alloying Equipment | |

| EAF-SCRAP | Electric Arc Furnace used with Scrap | EAF-PRIMARY | Electric Arc Furnace used with Green Iron / Hot Briquetted Iron |

Download

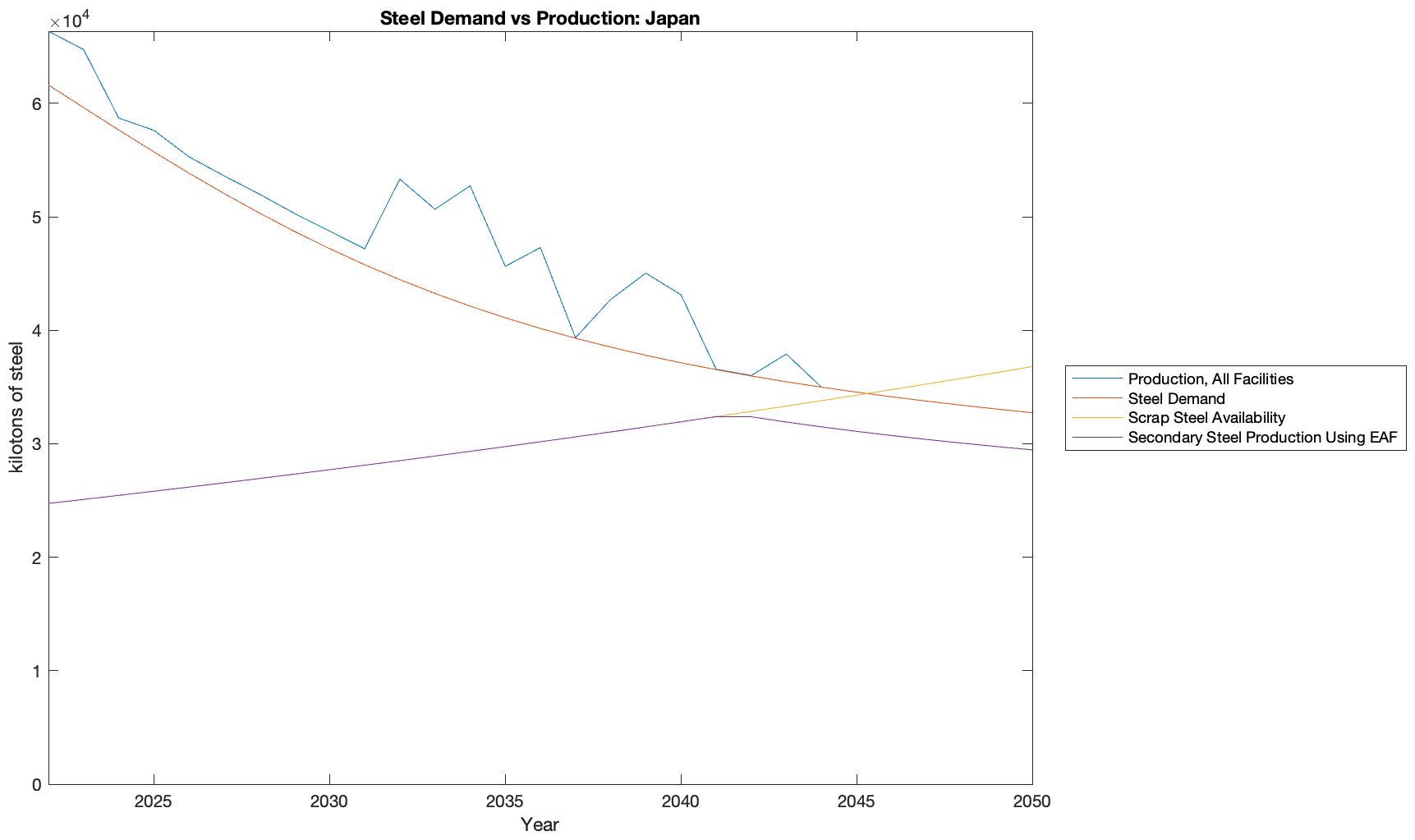

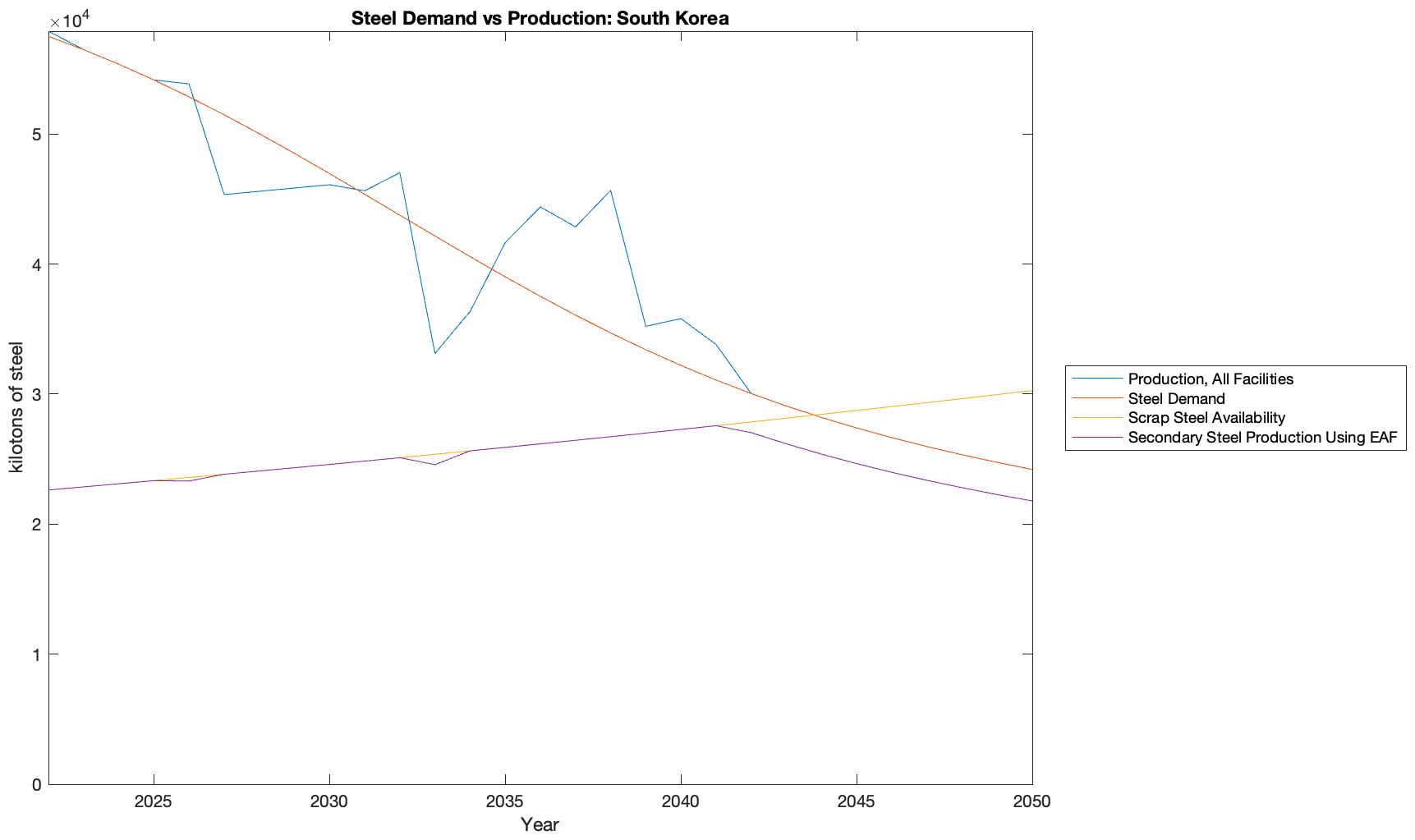

Main countries' results (s3)

Download

Detailed countries' results

Please select a scenario, an indicator and a country (or area).

Total steel produced by technology type, expressed as a percentage of the total manufacturing fleet.